Plant List

A list of measuring equipment and support tools held by AB Technology, including working volumes, sensors, software, and traceability details.

Overview

We operate a range of Coordinate Measurement Machines (CMMs) and 3D Scanning systems to cover most inspection and reverse engineering work. All our equipment is kept in our temperature controlled laboratory and is regularly calibrated and maintained under our ISO 9001 quality system.

Our High Precision Coordinate Measurement Machines (CMMs)

For high precision and high volume projects, we use our fully automated CMM systems with OEM UKAS calibrations and traceability to international standards.

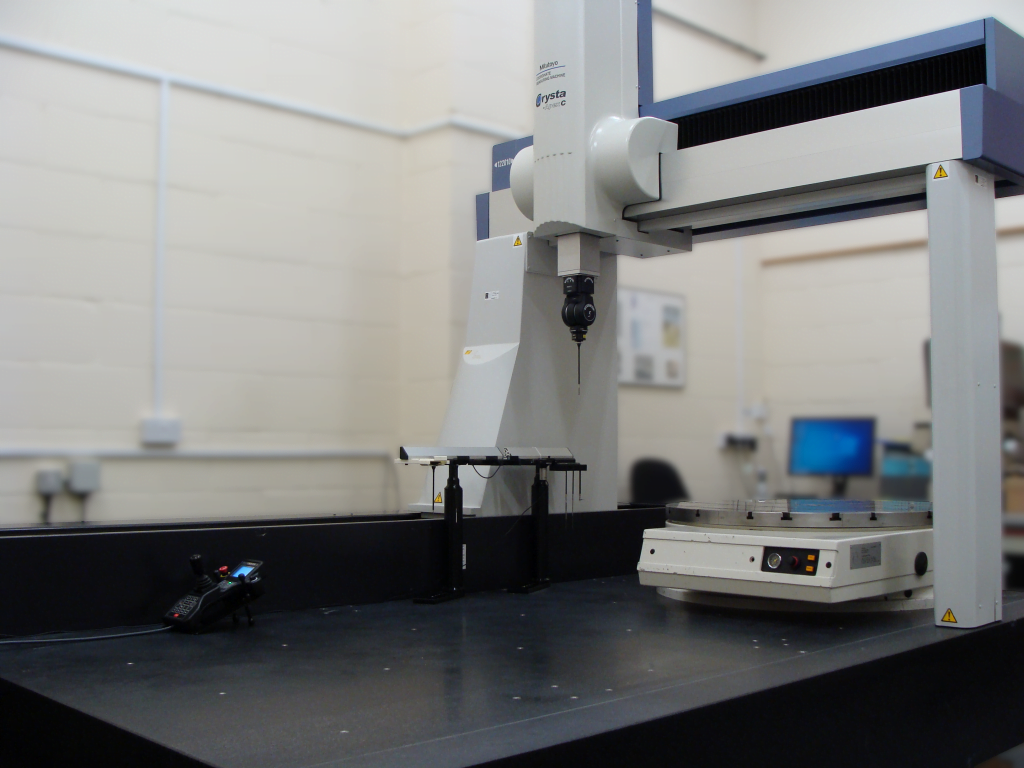

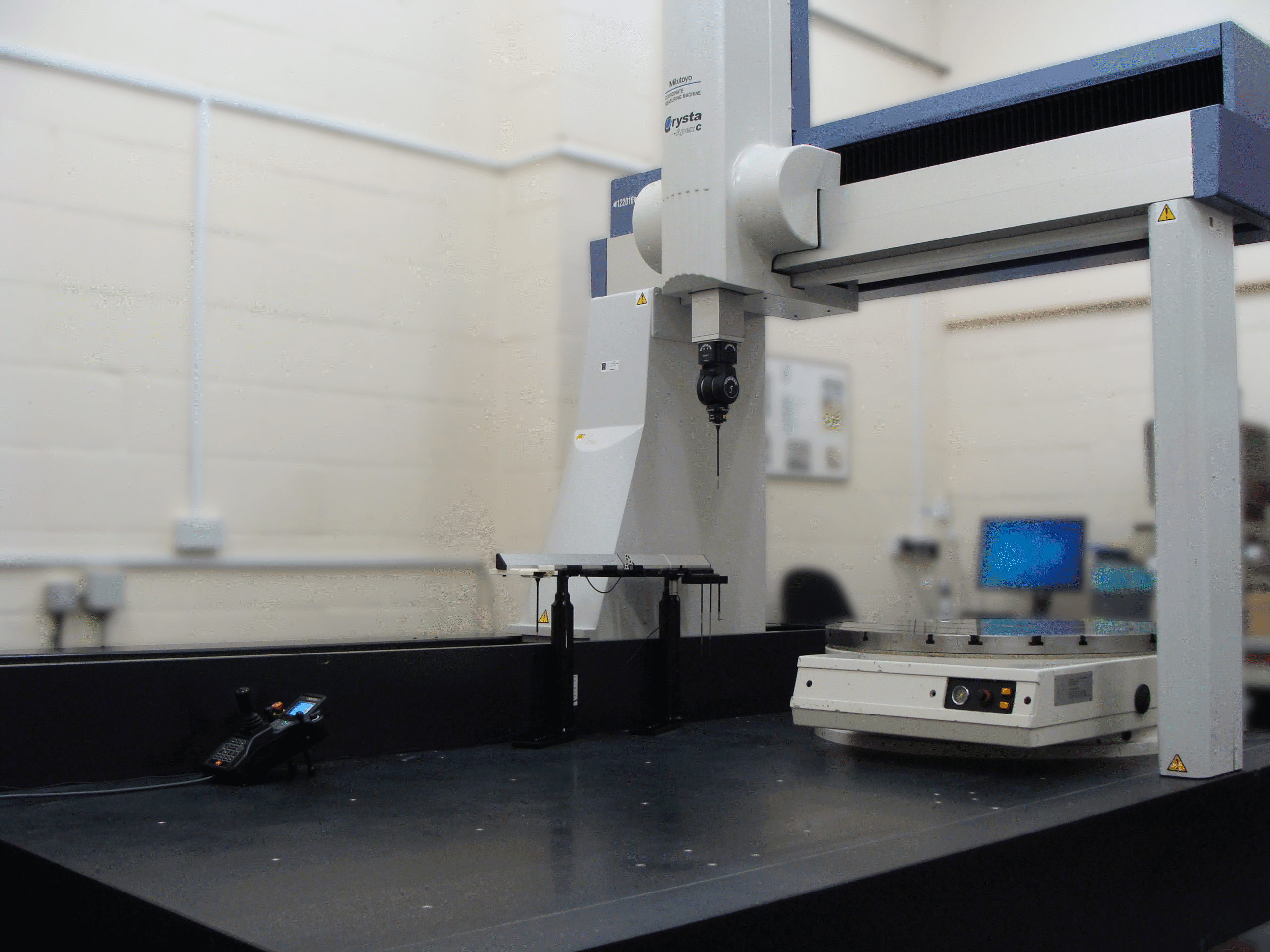

Mitutoyo Crysta Apex with REVO-2

Best for: High Precision Inspection

Our largest CMM offers micron-level accuracy across a 2 metre working volume, reliably measuring features as small as 0.4 mm. With its continuous indexing 5-axis scanning head, it provides greater flexibility to access features for measurement, enabling high-speed data capture across a wide range of component sizes and geometries.

Calibration

OEM UKAS Calibration (ISO 10360) traceable to international standards.

Key Specifications

- Accuracy: From 2.3 µm

- Working volume: 1200mm x 2000mm x 1000mm

- Probe head: REVO-2

- Sensors: RSP2, RPS3

- Scanning Capability: 5-axis

- Temperature Compensation: Yes

- Rotary Table: Yes

- Software:

- I++ UCCserver

- Renishaw Modus

- MeasureMax (via MMclient)

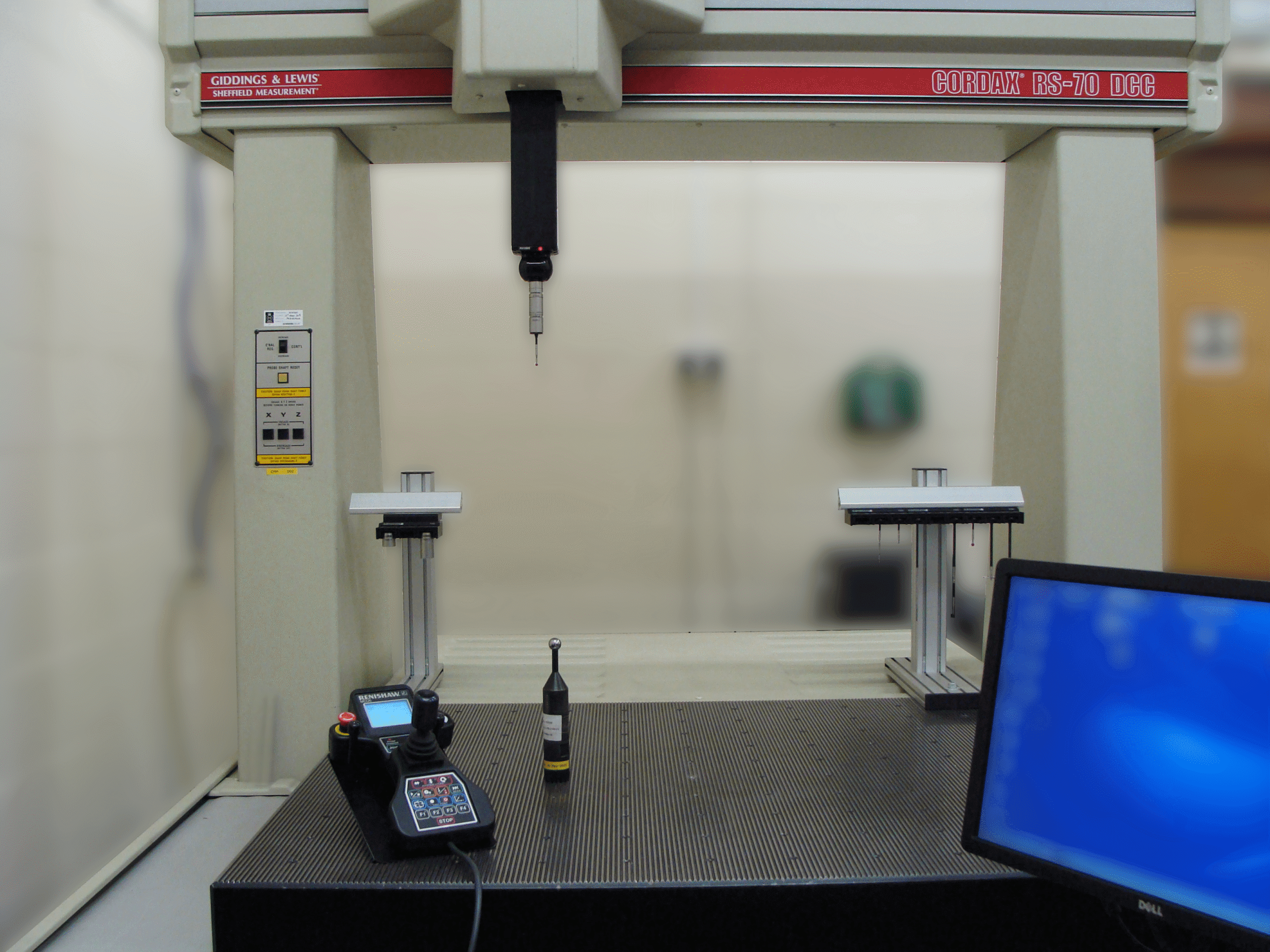

Sheffield RS-70 with PH10MQ

Best for: High Volume Inspection

A fast, flexible CMM for a wide range of components. It combines the high-speed TP20 point measuring sensor with the scanning SP sensors to capture high-density data, providing accurate and efficient measurement of both simple and moderately complex parts.

Calibration

OEM UKAS Calibration (ISO 10360) traceable to international standards.

Key Specifications

- Accuracy: From 3.5 µm

- Working volume: 1200mm x 1000mm x 1000mm

- Probe head: PH10MQ

- Sensors: TP20, TP200, SP25-1, SP25-2, SP25-3

- Scanning Capability: 3-axis

- Software:

- I++ UCCserver

- Renishaw Modus

- MeasureMax (via MMclient)

Our Professional 3D Scanning Equipment

We use professional-grade Shining 3D scanners, selecting the optimal technology for each project

Shining 3D EinScan HX

Handheld Hybrid Laser Scanner

Our versatile handheld scanner featuring hybrid blue laser and LED structured light technology, ideal for challenging surfaces and larger objects.

- Accuracy: Up to 0.04 mm

- Resolution: 0.05 mm point distance

- Speed: 1,200,000 points/second

- Technology: Hybrid laser & LED

- Features: Built-in colour camera

- Portability: Fully portable for on-site work

Best for: Castings, machined parts, medium to large objects, industrial components, automotive parts

Shining 3D TranScan C

Desktop Structured Light Scanner

Our high-precision desktop scanner designed for capturing exceptional detail on small to medium objects with professional quality results.

- Accuracy: 0.035 – 0.05 mm

- Resolution: 0.0375 mm point distance

- Scan range: 150×96 to 300×190 mm

- Technology: White structured light

- Features: Dual 12 MP colour cameras

- Portability: Fully portable for on-site work

Best for: Small intricate parts, precision components, detailed features, jewellery, consumer products

Other Measurement Tools

Beyond our CMMs and 3D scanners, we maintain a comprehensive range of calibrated hand tools and bench-mounted equipment to support all aspects of dimensional measurement and quality control.

Mitutoyo Profile Projector

Our optical profile projector allows precise measurement and inspection of small components, with particular effectiveness on chamfers, radii, and other fine features.

Calibrated Hand Tools

All tools are maintained to ensure traceability and accuracy, supporting manual inspection work, setup verification, and dimensional checks alongside our CMM and 3D scanning capabilities.

Need precision measurement equipment for your project?

Our equipment is ready to handle projects from small precision components to large industrial parts. Contact us to discuss your inspection requirements.