3D Scanning Services

Our 3D Scanning Services

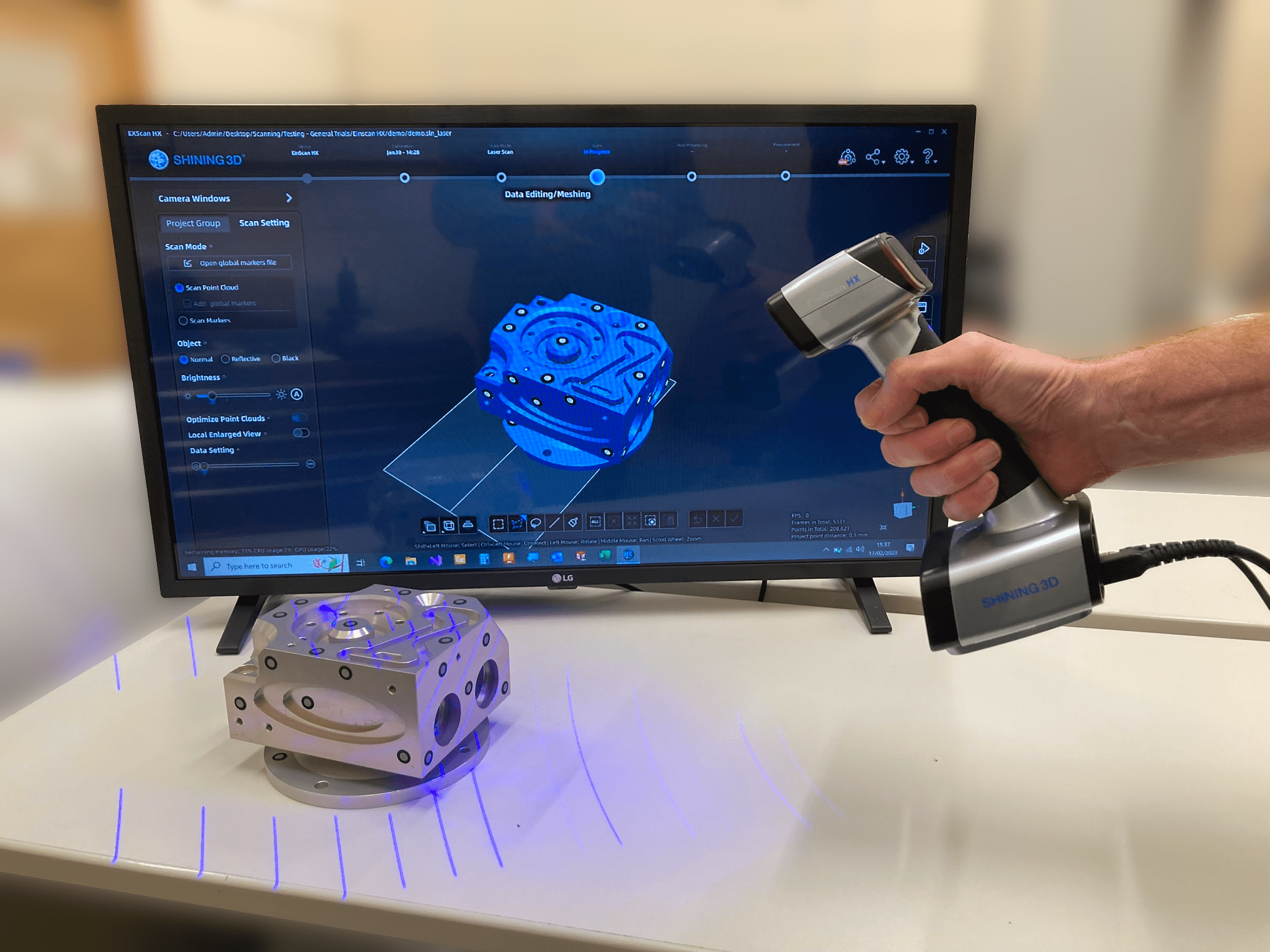

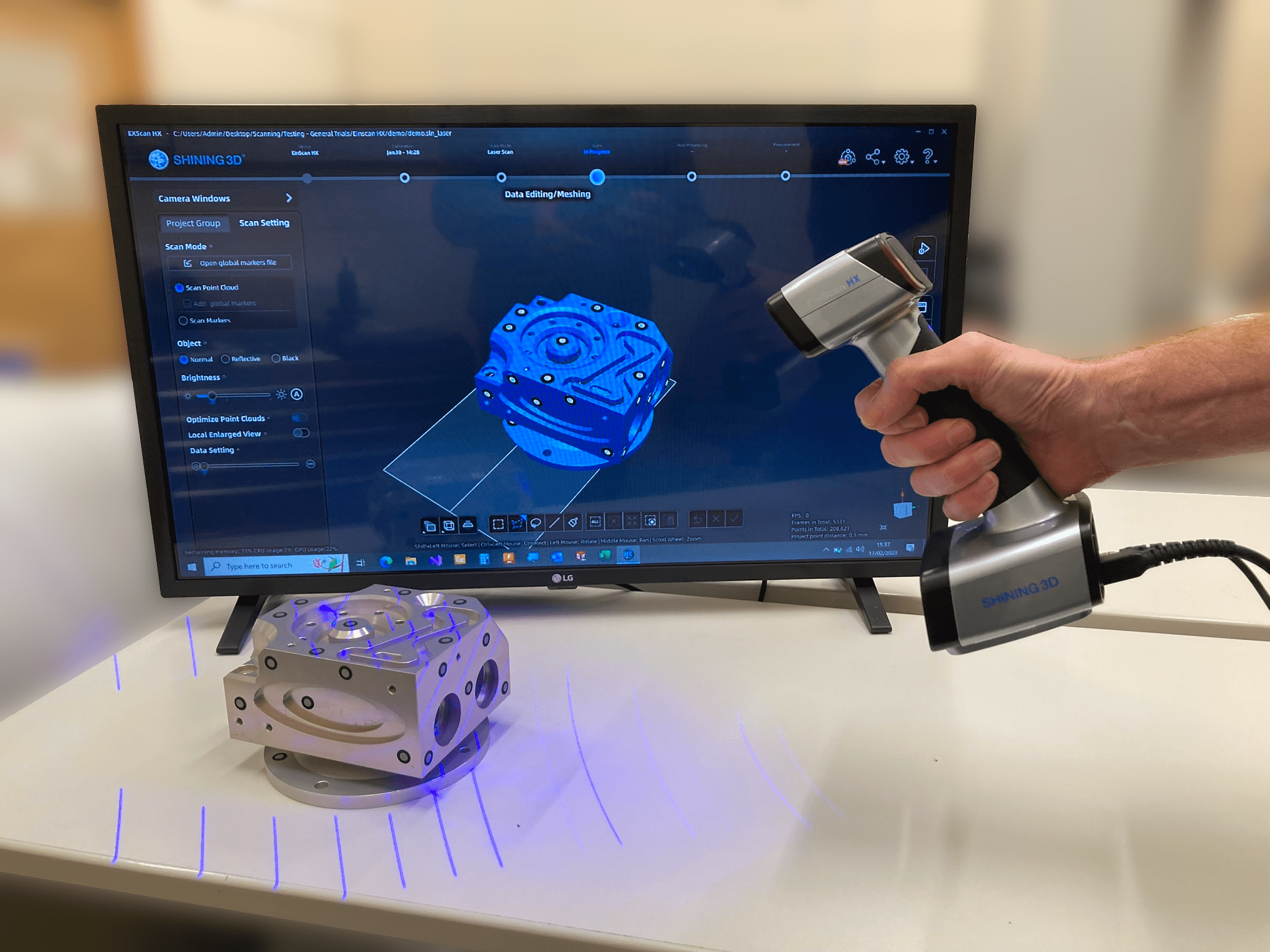

Our UK based 3D scanning services provide fast, accurate and cost-effective ways to digitise your physical object for 3D printing, CAD modelling, reverse engineering and more. We offer both on-site and in-house scanning services using structured blue light, blue laser and full colour texture scanning, meaning the scope of things we can scan is extensive.

Scan to STL Mesh

Creating high-quality, detailed 3D models from your physical objects through our state-of-the-art 3D scanning services.

Scan to CAD

Turning 3D scan data into parametric CAD models that can be customised and optimised for manufacturing and product development.

Compare To CAD

Gain a detailed understanding of the differences between your manufactured component and its design intent CAD.

3D Scanning for 3D Printing

We create digital models for 3D printing using 3D scanning. Whether you need an exact replica of an object or a fully editable CAD model, we provide files that you can print, modify, keep, and use as you need.

Your Complete 3D Scanning UK Service Provider

We offer a complete 3D scanning service for projects of all shapes, sizes, and materials. From generating a point cloud of your object, digitising your product as an STL mesh, through to a fully reverse engineered parametric CAD model. We are experienced in utilising the latest hardware and software to bringing your physical object into the digital world.

Small detail

Delivering high-quality scans of small objects including model cars, machined components and even biscuits with our advanced 3D scanning services, ensuring that no detail is lost.

Medium size

Our 3D scanning services are ideal for creating high-quality 3D CAD models of medium-sized objects, such as automotive components, consumer products, and much more.

Large projects

Trust us to scan and digitise your large and complex objects with precision and expertise. From industrial machinery to large parts, we have experience in delivering solutions.

To discuss your 3D scanning project, get in touch today.

Or visit our 3D scanning portfolio to see example of our work.

Frequently Asked Questions

Can you scan my part?

Yes. With our unique combination of desktop scanners, handheld laser scanners, and CMMs there’s very little we can’t scan. We have scanned everything from hobbyist models, to precision machined components, to large complex assemblies. See our Case Study and 3D scanning portfolio pages for more examples of our work.

Can you scan my shiny / matt black / transparent part?

Yes, we can scan virtually any surface, regardless of its material or finish. For parts that would otherwise be difficult to scan, we use a specialist self-evaporating spray that leaves zero residue on the object’s surface. This spray helps to enhance the object’s features and make it easier to scan accurately.

We’re confident that we can scan even the most challenging objects, from highly reflective surfaces to transparent materials. If you’re unsure whether your object can be scanned, please contact us to discuss your project. We’ll work with you to find the best solution for your needs.

How much does 3D scanning cost?

The main factors that affect cost are the size, complexity, and level of detail of your part.

To get an accurate quote for your project, please send us some photos and a brief description of your part and its intended use via our contact form. We’ll be happy to advise you on the best file format for your 3D scan data and provide a detailed quote that meets your needs.

Our prices include all costs associated with the project, including scanning, processing, and file delivery. There are no hidden fees.

Do I need to send you my part or can you do on-site 3D scanning?

We provide both in-house and on-site 3D scanning services to suit your needs. The most cost-effective option is to send your part to us, but we are also happy to come to your site and scan your parts if necessary. Contact us to discuss the best option for your project.

Can you provide a fast turnaround?

We understand the importance of meeting deadlines, and we can work with you to provide a fast and efficient service tailored to your needs. If you’re working to a tight schedule, give us a call on +44 (0)1623 491700 for a quote and we’ll do our best to accommodate your needs. We can often start as soon as the next day.

What file format do 3D scanners use?

We can output scan data in all common CAD file formats, including STL, OBJ, PLY, DXF, STP and IGES. You can download example files from our downloads page. If you need any other format please get in touch.

To find out more or request a quote

We are here to help.

About Us

AB Technology started out as an independent CMM Inspection & Programming company based near Nottingham, UK. Over the last 30 years, we have expanded our services to include 3D scanning and reverse engineering, serving customers of all sizes, across an array of industry sectors, both domestically and internationally.

Key Links

Contact Us

AB Technology (Newark) Ltd.

Unit 8, Crewe Close

Blidworth

Nottinghamshire

NG21 0TA

United Kingdom