CMM Inspection Services

CMM inspection services at AB Technology use the latest Renishaw probing equipment to meet all your dimensional inspection needs.

Our dimensional inspection services are used to ensure your products conform to their design specification and to solve manufacturing issues.

Why use a subcontract CMM Inspection Service?

A coordinate measuring machine (CMM) can bring a range of benefits to your business. By accurately measuring your object you gain a reliable & detailed assessment of your component that you can use to make business decisions that are truly evidence based. From product development to production control, let our expert CMM Inspection Service be your independent eyes.

Whether your in-house capacity is full, you don’t have the necessary equipment in house, or you’re seeking an independent inspection, we are here to help. Contact us today. Our experienced Engineers are here to assist you. We want your project to be a success.

CMM Inspection Services Offered

- 1-off component measurement

- Batch/multi component inspection

- High volume production service

- Production Part Approval Process (PPAP)

- First Article Inspection (FAI & FAIR)

- Last Article Inspection (LAI & LAIR)

- Initial Sample Inspection (ISI & ISIR)

- Repeatability and Reproducibility Studies (Gauge R&R)

- Measurement System Analysis (MSA)

- Statistical Process Control (SPC)

- Root cause analysis

- Independent correlation

- Quality containment and resolution

- Development of inspection procedures for new products

- Reverse engineering

Over 25 years experience

Our precision inspection service is based on over 25 years experience gained across multiple industries, from plastic moulding manufacturing through to critical flight parts in aviation. We work with our customers start to finish to create inspection plans, design fixture assemblies, and carry out component inspection.

The latest technology

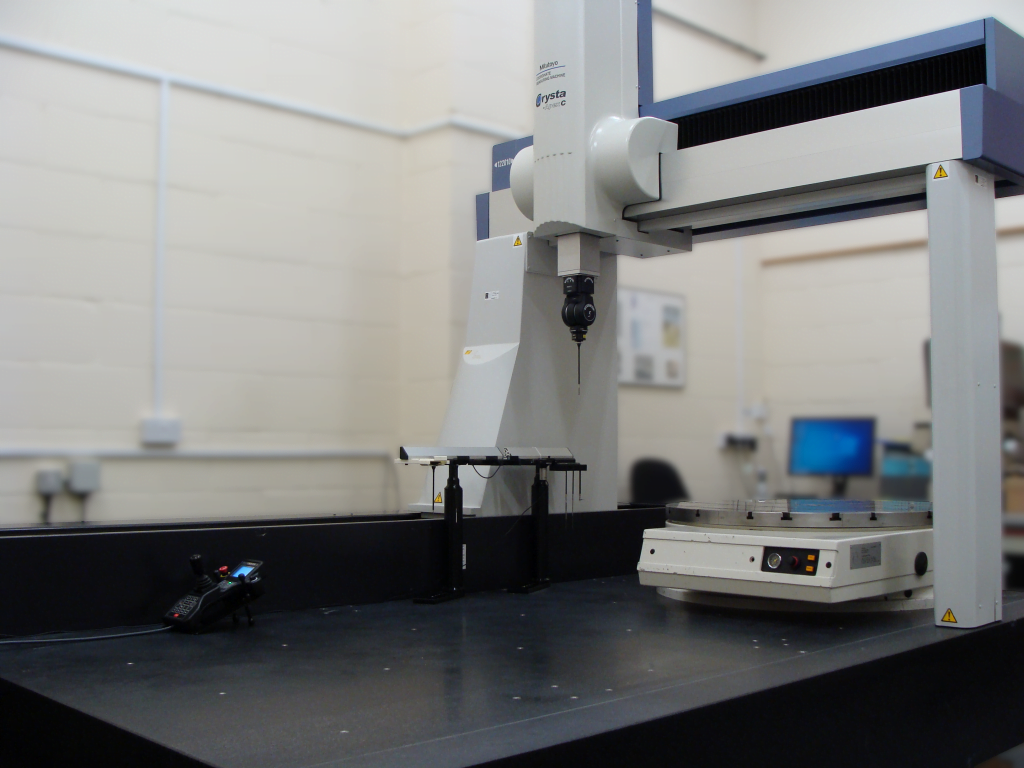

Investment in the latest software allows our engineers to work seamlessly with your component definition and inspection requirements, handling CAD and Drawing definitions. Our CMM’s are equipped with a range of measuring technologies including the latest Renishaw REVO-2 probe head with its unique ability to offer full 5-axis scanning. Combining all these elements allows us to deliver a high integrity inspection process with easy to understand reports.

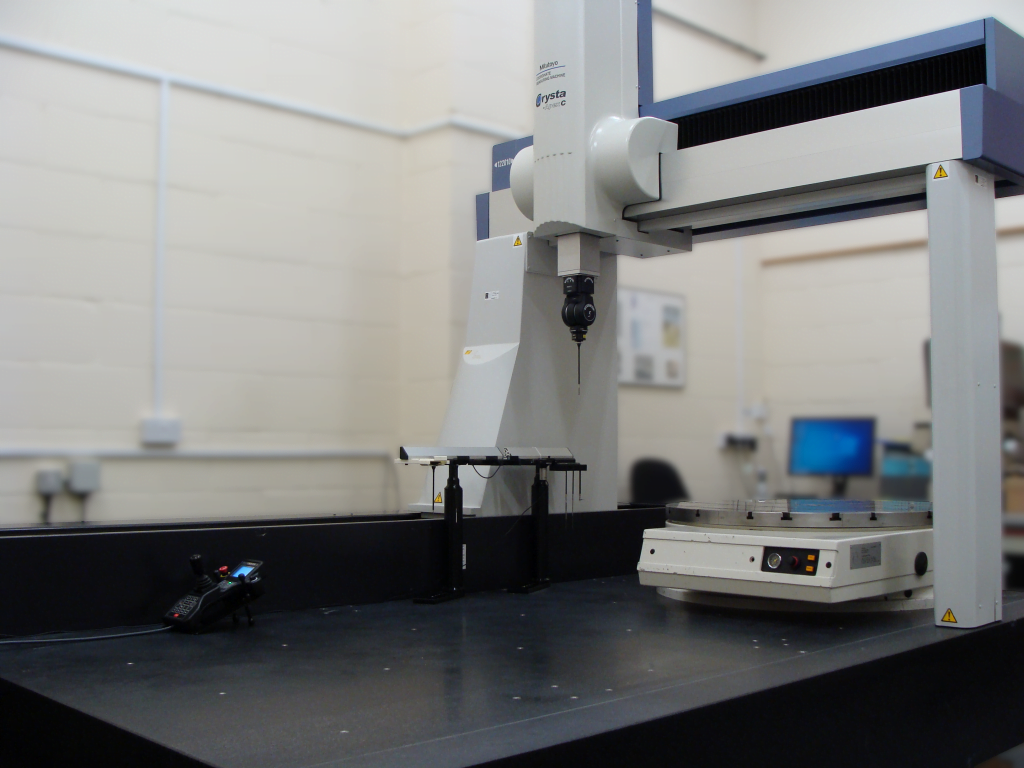

Mitutoyo Crysta Apex with REVO2

- 1200mm x 2000mm x 1000mm working volume

- OEM UKAS Calibration

- Extremely High accuracy

- 5 Axis REVO-2 scanning head

- RSP2 and RPS3 scanning sensors

- Temperature Compensation

- Rotary Table

- Software:

- I++ UCCserver

- Renishaw Modus

- MeasureMax (via MMclient)

Sheffield RS-70 with PH10MQ

- 1200mm x 1000mm x 1000mm working volume

- OEM UKAS Calibration

- High accuracy

- PH10MQ head

- SP25-1, SP25-2 and SP25-3 scanning sensors

- TP20 and TP200 point measuring sensors

- Software:

- I++ UCCserver

- Renishaw Modus

- MeasureMax (via MMclient)

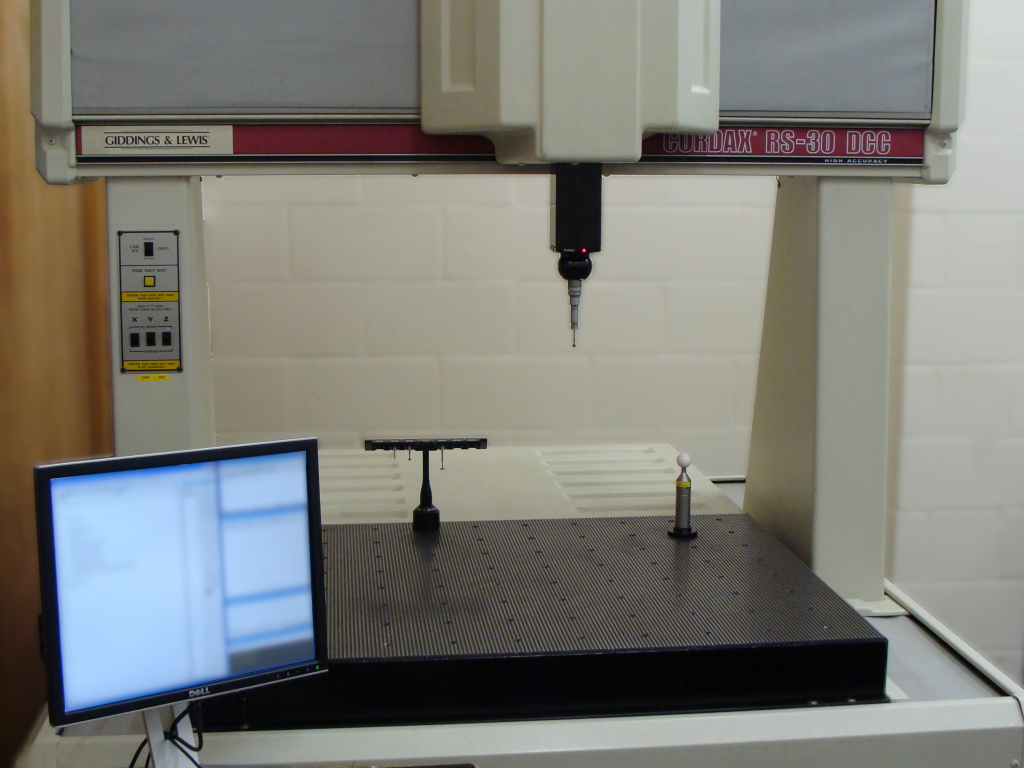

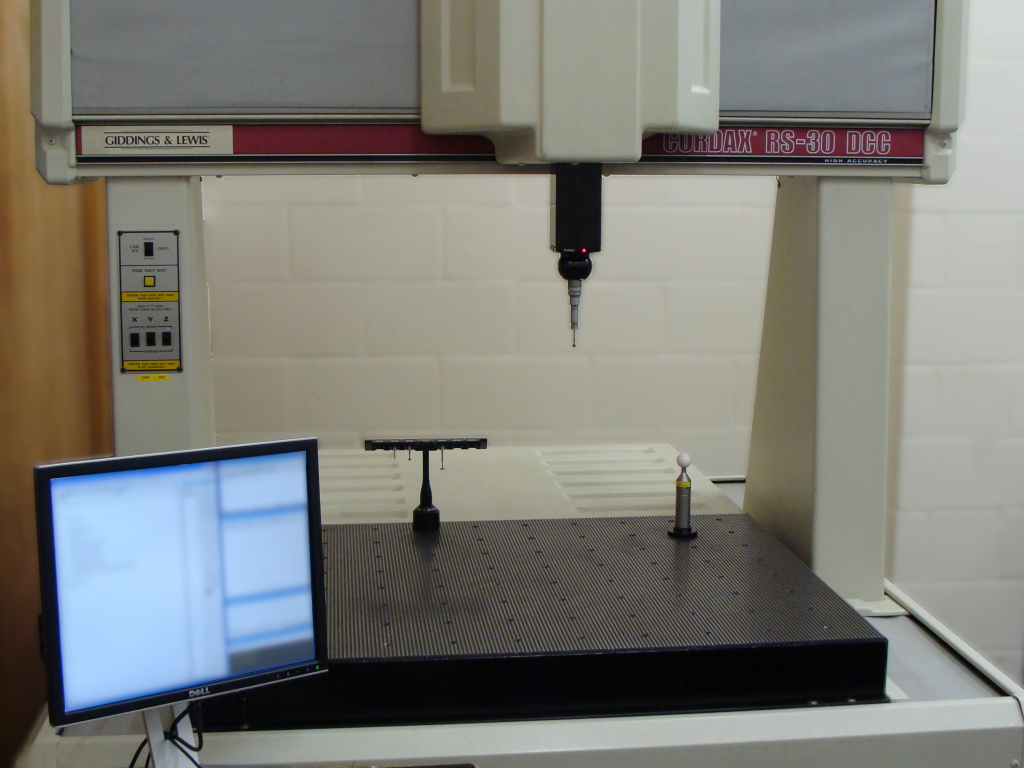

Sheffield RS-30 with PH10MQ

- 700mm x 1000mm x 600mm working volume

- OEM Calibration

- Extremely high accuracy

- PH10MQ head

- TP20 and TP200 point measuring sensors

- Temperature Compensation

- Software:

- MeasureMax

Our Industries

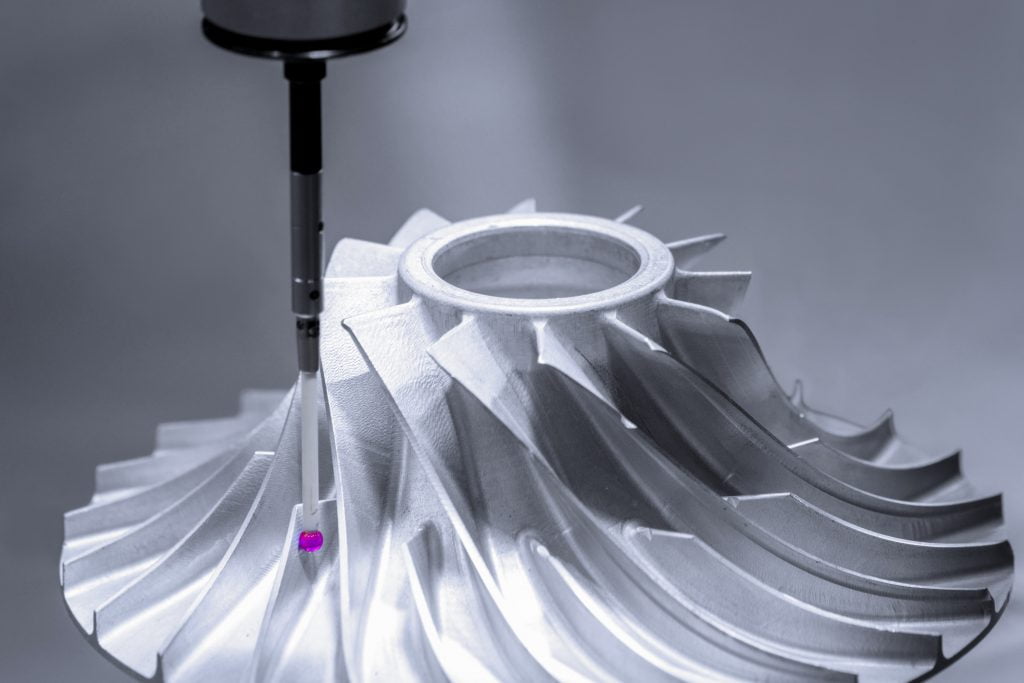

Aerospace

- Blisks

- IBRs

- Fan & Turbine Discs

- Fan, Compressor & Turbine Blades

- Fir Tree Roots

- Stub shafts

- Nozzle Guide Vanes

- Bearing housings

- Casings, Housings & Structures

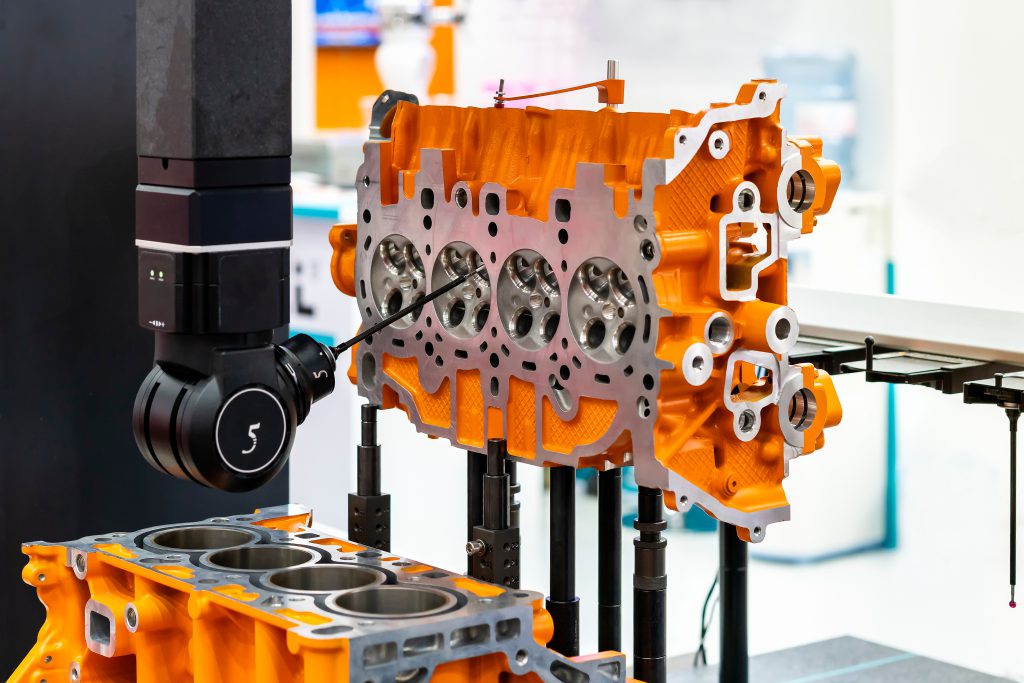

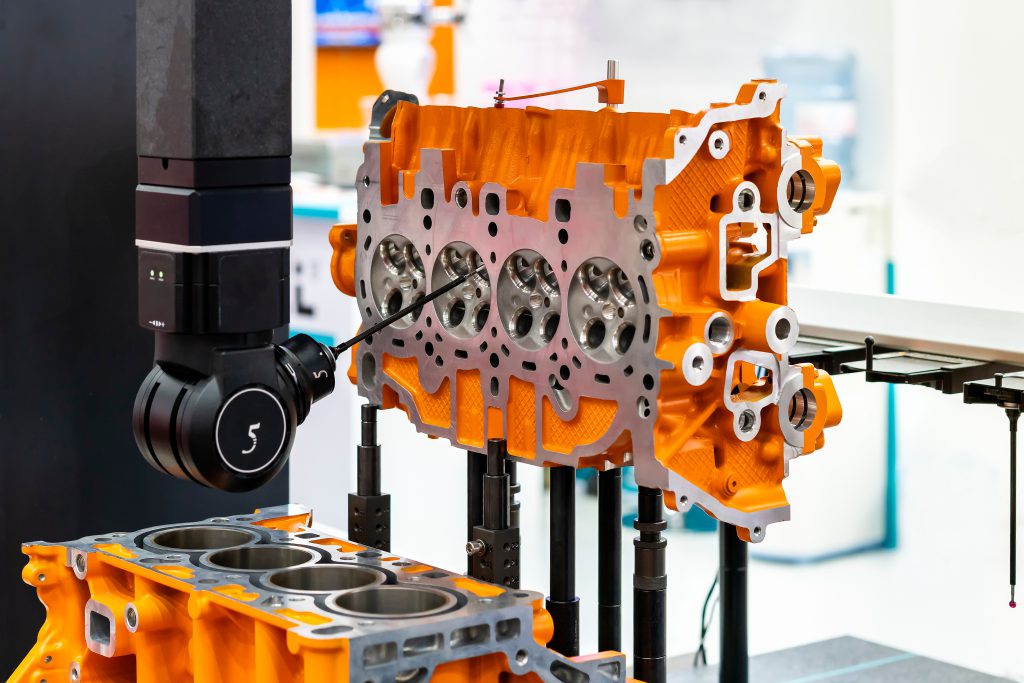

Automotive

- Turbo chargers

- Cylinder heads

- Gearbox housings

- Engine blocks

Manufacturing

- Plastic mouldings

- Injection moulding components

- Metal & Plastic Casings

- Castings

- Manufacturing Fixturing

Other Industries

- Oil & Gas

- Defence

- Consumer products

- Medical

- Universities

- R&D

To find out more

We are here to help.

About Us

AB Technology started out as an independent CMM Inspection & Programming company based near Nottingham, UK. Over the last 30 years, we have expanded our services to include 3D scanning and reverse engineering, serving customers of all sizes, across an array of industry sectors, both domestically and internationally.

Key Links

Contact Us

AB Technology (Newark) Ltd.

Unit 8, Crewe Close

Blidworth

Nottinghamshire

NG21 0TA

United Kingdom