First Article Inspection Services

Our First Article Inspection Service is designed to make your life easy. When you’re introducing a new or improved production line, we help ensure you’re producing quality products from the first part, protecting your business and your reputation.

Full service First Article Inspection provider

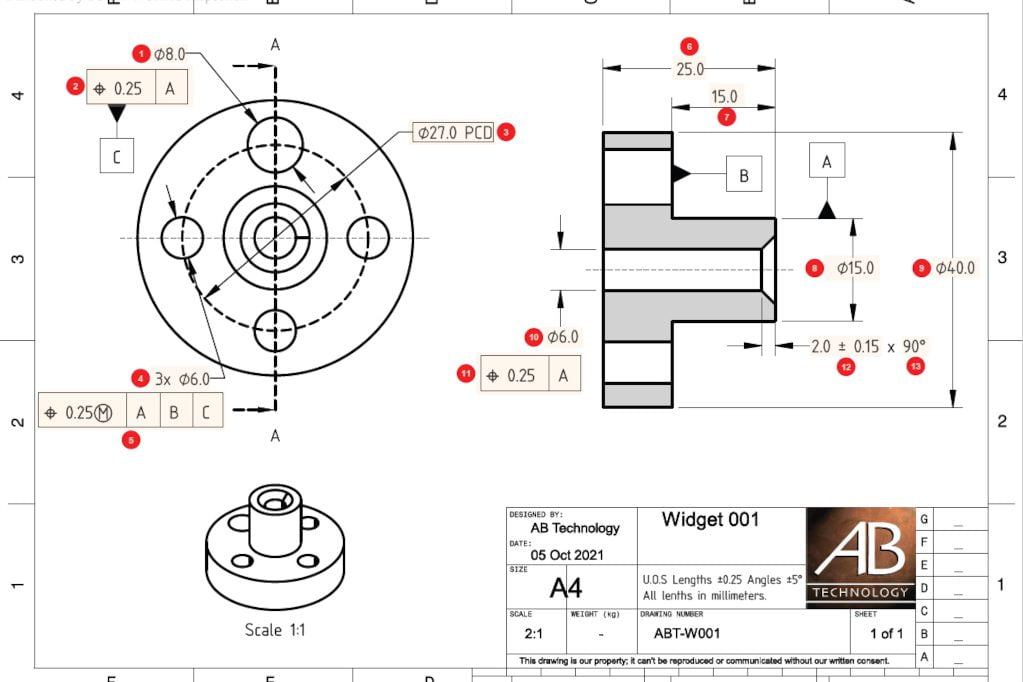

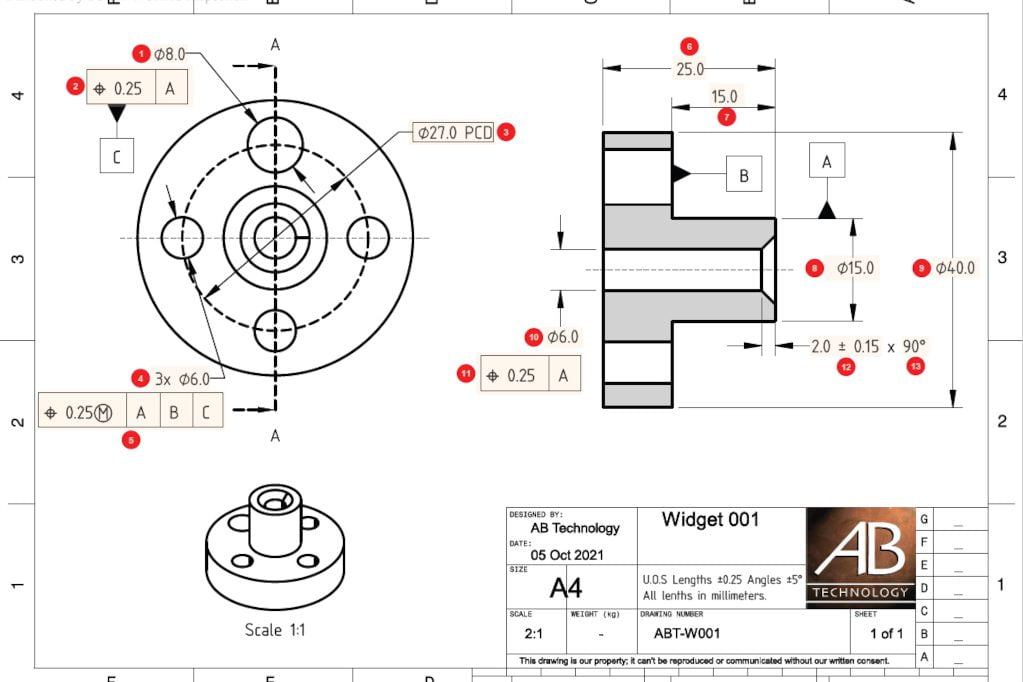

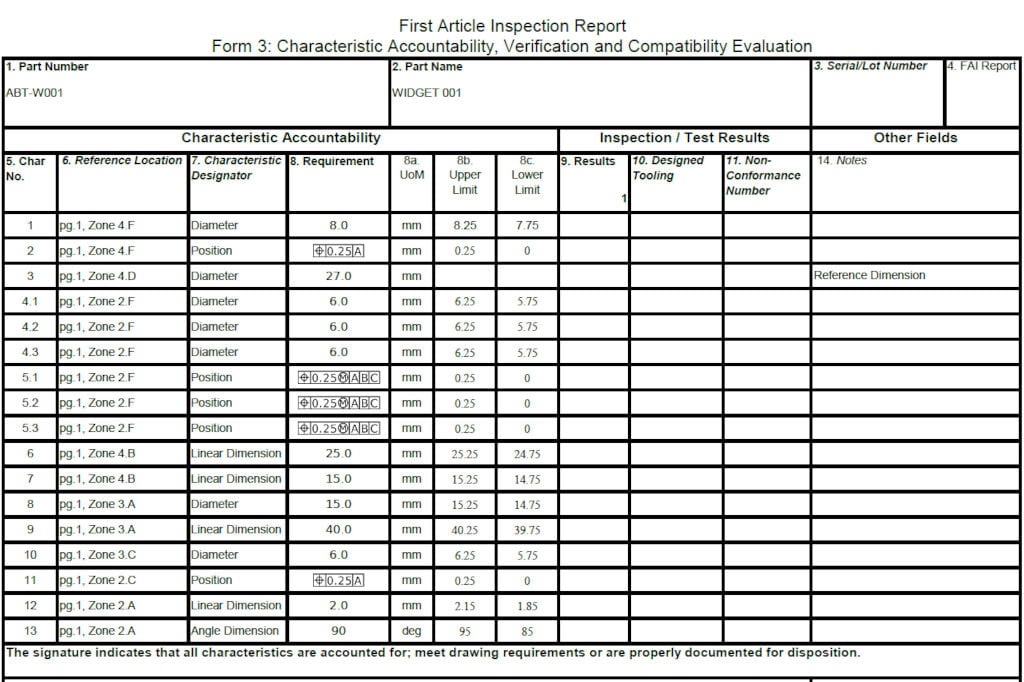

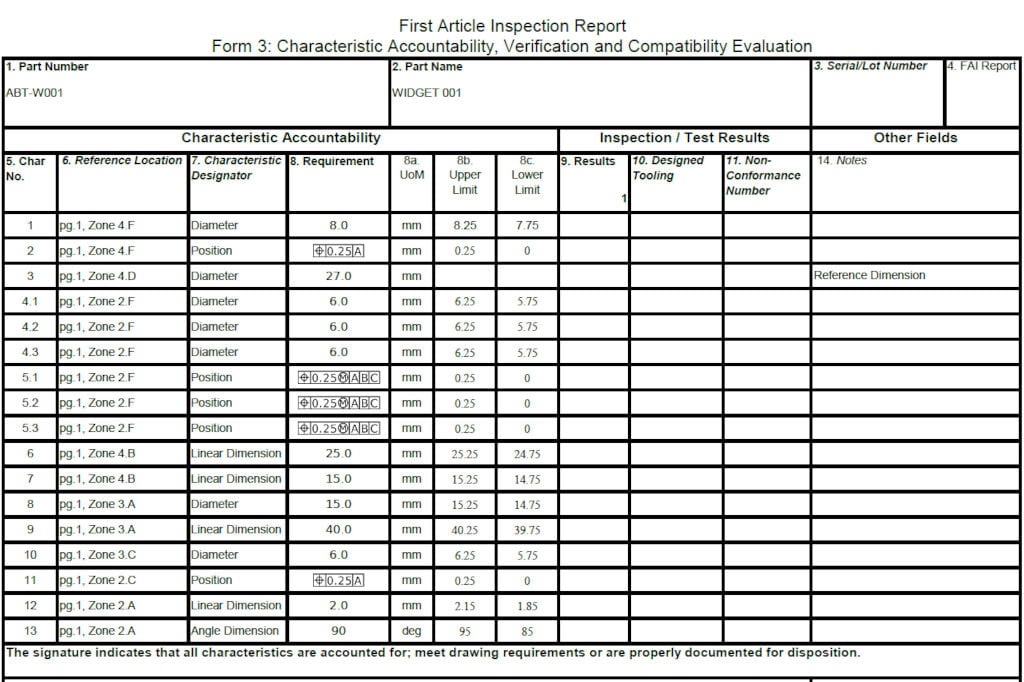

Generating and completing First Article Inspection Reports (FAIRs) is a core part of our business at AB Technology. We offer a full service First Article Inspection package. From generating your ballooned drawings and report templates, creating all inspection programs and procedures, through to populating FAI reports for you. We are experts at helping you through this vital milestone in the production process.

If your customer has requested a First Article Inspection contact us for support.

Do you need a First Article Inspection Report?

First Article reports are normally required after your first production run, once all process development has been competed. A full or partial FAIR should also be carried out if any changes are made to an existing production process. Our FAI reports help you to mitigate risk by verifying your production process is producing conforming parts.

An FAI report is often a customer requirement determined by the relevant quality management procedures, such as PPAP in the automotive industry or AS9100 in the aerospace industry. The FAIR details the conformance of the product to the drawing requirements, giving both you and your customer confidence in the production process.

You should consider conduct a FAIR when:

- Your new production process has been finalised

- You make any change that may affect the form, fit, or function of your product including:

- Change of manufacturing process

- Change of inspection method

- Change of supplier

- Change to production location

What you can expect from our First Article Inspection service

- Ballooned copies of your drawings (if required)

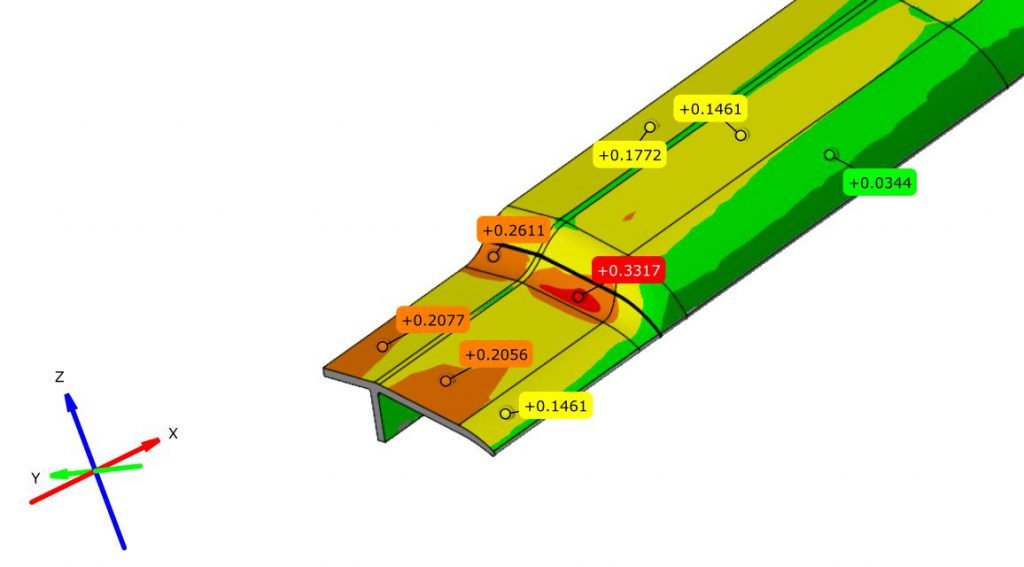

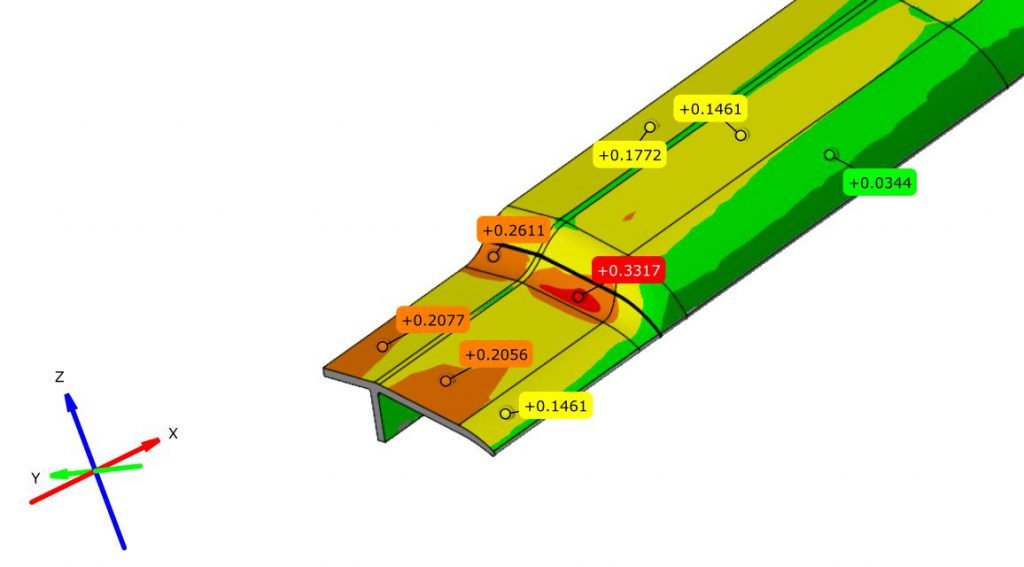

- Measurement of design characteristics using our in-house dimensional inspection service

- A populated first article inspection report (often referred to as a Form 3 or FAIR)

- Optional csv & pdf reports to support your engineering and manufacturing teams

How we will complete your First Article Report

We will fully inspect your sample part (or a sample from the first batch of parts) against your part drawing requirements. Unless specified, all features will be checked against the associated drawing tolerances by inspecting the part(s) using methods such as CMM inspection, non-contact inspection (3D laser scanning), or hand tools (vernier calipers, micrometers, projectors). Once we have completed the inspection process, we will populate your Form 3 report for you to review.

Last Article Inspection?

If you are modifying an existing production process in such a way that a new FAIR will be required, we recommend completing a Last Article Inspection (LAI) report prior to making any changes. Last Article Inspection reports are completed in much the same way as a First Article Inspection, except as the name implies, the last part (or a sample from the last batch) is inspected. Having both a FAI and LAI report gives you definitive and quantifiable before and after results for your modification.

Let’s work together on your

next project

For a free no obligation quote

About Us

AB Technology started out as an independent CMM Inspection & Programming company based near Nottingham, UK. Over the last 25+ years, we have expanded our services to include 3D scanning and reverse engineering, serving customers of all sizes, across an array of industry sectors, both domestically and internationally.

Key Links

Contact Us

AB Technology (Newark) Ltd.

Unit 8, Crewe Close

Blidworth

Nottinghamshire

NG21 0TA

United Kingdom