CMM Programming Services

Our CMM programming services combine expert knowledge and part programming skills to produce efficient and robust CMM programs to meet your needs.

We offer both off-line and on-site programming services.

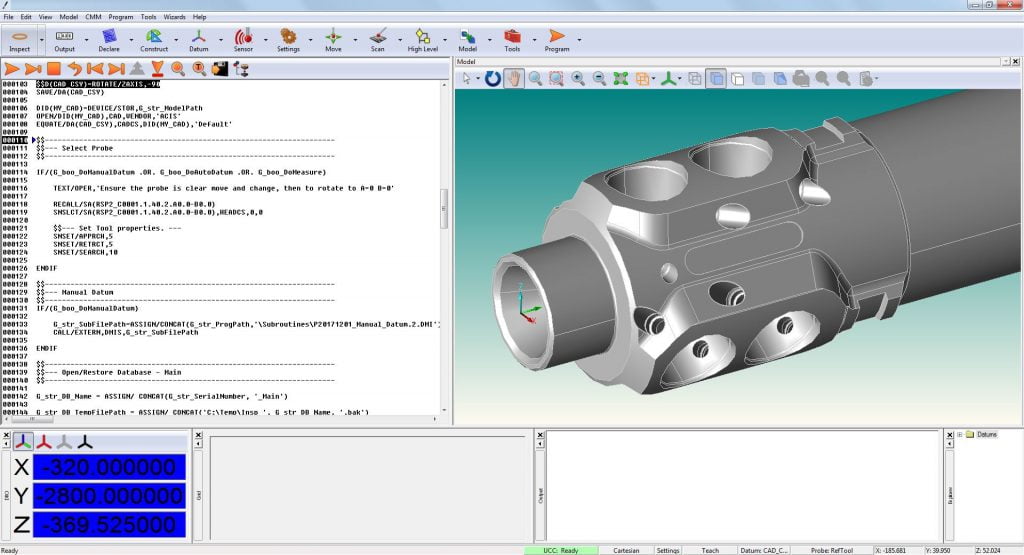

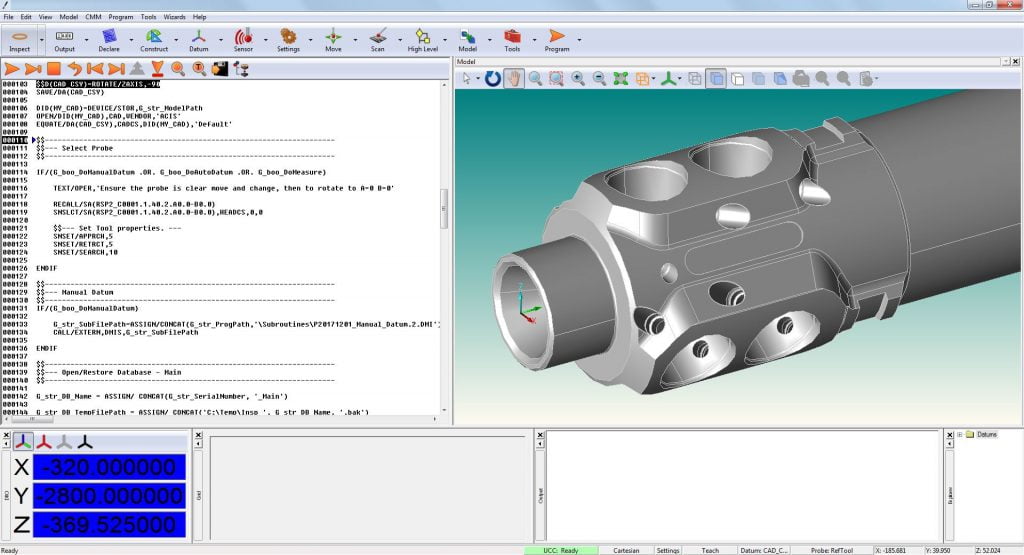

ABT’s subcontract CMM programming services combines expert knowledge and part programming skills to produce efficient and robust CMM programs. From 1-off inspections to volume production our CMM programming service will deliver. We are experts at utilising Renishaw PH20, REVO and REVO-2 systems to measure any part. Programming onsite or remotely in the DMIS based Modus software, our engineers will write an efficient and robust CMM program.

Our offline CMM programming and simulation software enables us to create inspection programs from your CAD model or drawing prior to your part being available. Once your physical component becomes available the CMM measurement program is ready to go live meaning you benefit from a reduced lead-time and enabling you to maximise your productivity.

Modus CMM Programming

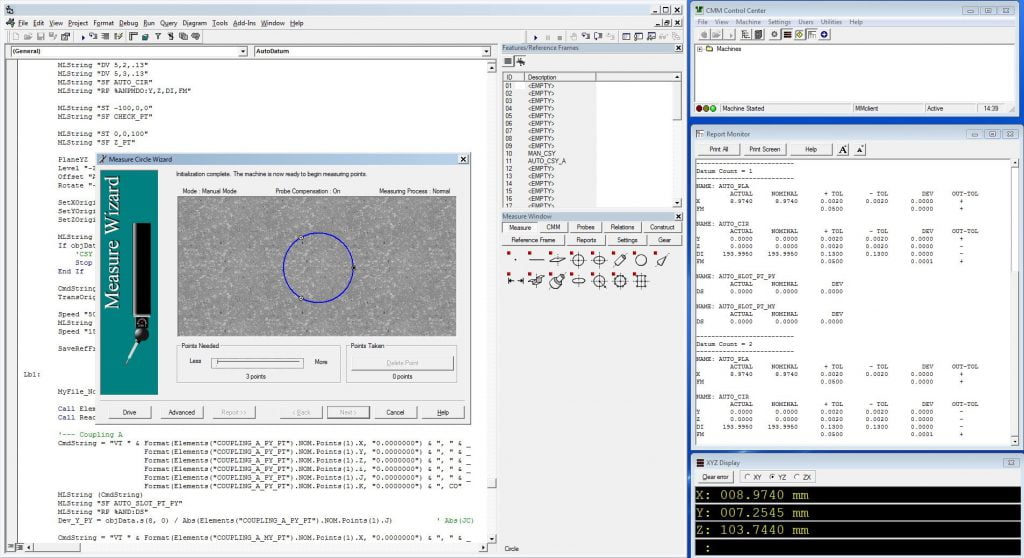

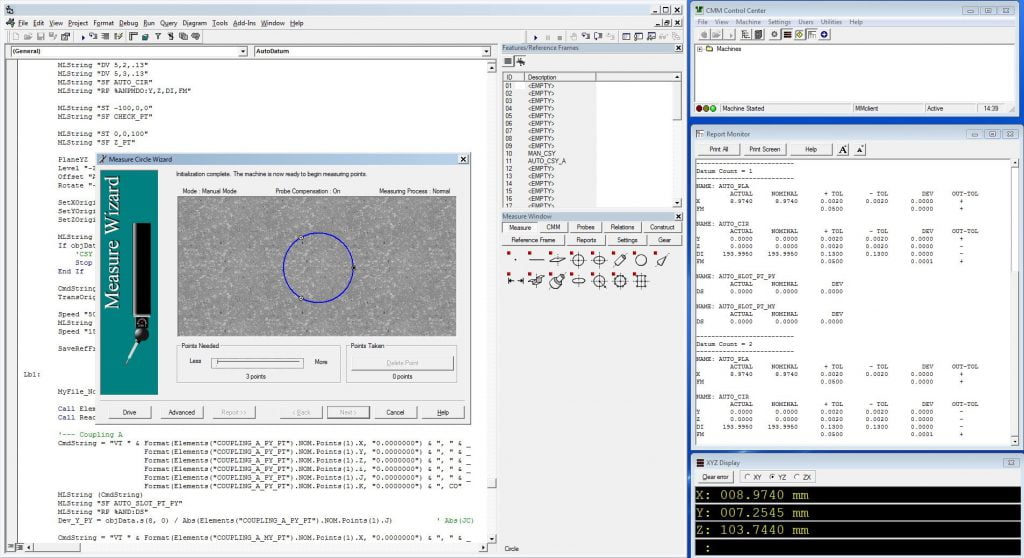

MeasureMax CMM Programming

Made with efficiency and maintainability in mind

Our CMM programmers have decades of experience of writing production Modus, Quindos, and MeasureMax measurement programs. We know the difference a high quality, well structured and easy to follow program can make to the efficiency of your inspection process. All our part programs are written so once delivered, your operators should be able to maintain and upgrade them in the future. No nasty surprises or tricks to keep you tied. We rely on our reputation as a good honest supplier for dimensional analysis.

Delivering excellence into your inspection facility

Having already used our offline programming and simulation software to create and optimise your CMM measurement program and agree the reporting format with you, let us assist with commissioning the measurement program. We can prove out the measurement program at AB Technology’s inspection facility on one of our UKAS calibrated CMMs, or visit your site and commission the program directly on your own coordinate measuring machine. Finally let use demonstrate the robustness and quality of the measurement program with a reproducibility and repeatability study (Gauge R&R) or Measurement System Analysis to IS0 13003 (MSA).

Detailed reporting, including CSV as standard

We believe your CMM inspection process should add value to your business and not be an overhead. Having invested both time and money in creating a CMM part program, we ensure the inspection data is available to you in the formats you require. That is why CSV reporting is included with every program we write as standard. Its a simple to implement, simple to use method for tracking your results and essential for SPC.

Measurement Databases are also saved as standard in all our CMM programs. This gives your engineers the capability to access the raw measurement data enabling them to extract greater detail where necessary or perform a root cause analysis if required. We offer automatic PDF report generation, including visual plots of scanned inspection data, giving you greater insight. To make CMM inspection a valuable tool in controlling and optimising your manufacturing process contact us today.

Our CMM programming languages

- Renishaw’s Modus & UCC Server

- Sheffield’s MeasureMax

- Hexagon’s Quindos

- LK’s Camio

- Taylor Hobson’s Ultra, Talysurf CCI & PGI Matrix

- DMIS & I++ based software

Use another programming language? Challenge us!

First and foremost we are engineers with a passion for problem solving. If we can help, we will.

To find out more

We are here to help.

About Us

AB Technology started out as an independent CMM Inspection & Programming company based near Nottingham, UK. Over the last 30 years, we have expanded our services to include 3D scanning and reverse engineering, serving customers of all sizes, across an array of industry sectors, both domestically and internationally.

Key Links

Contact Us

AB Technology (Newark) Ltd.

Unit 8, Crewe Close

Blidworth

Nottinghamshire

NG21 0TA

United Kingdom