CMM Inspection Services

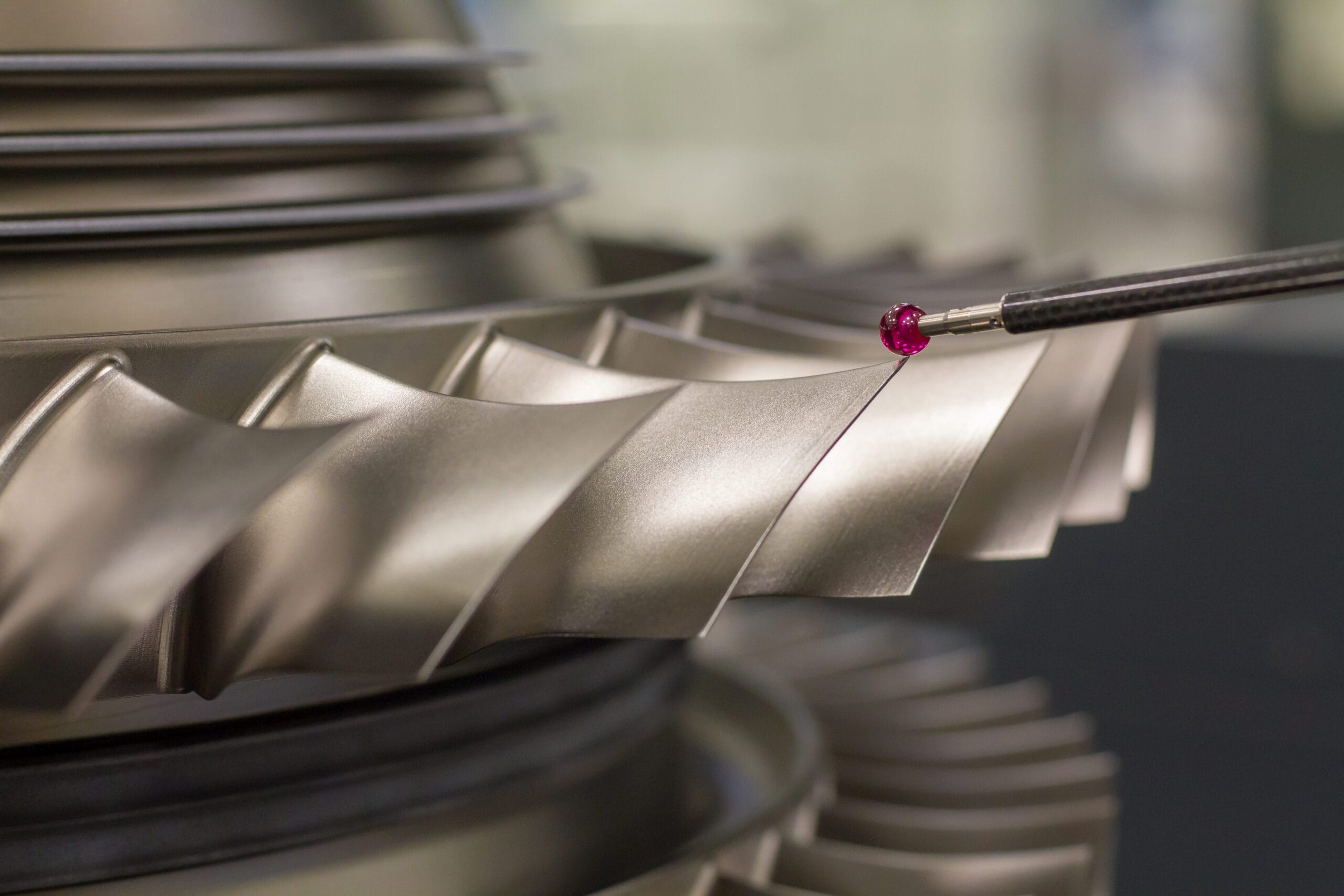

CMM inspection services at AB Technology use the latest Renishaw probing equipment to meet all your dimensional inspection needs.

Our dimensional inspection services are used to ensure your products conform to their design specification and to solve manufacturing issues.

Reasons For Using CMM Inspection Services

- 1-off component measurement

- Batch/multi component inspection

- High volume production service

- Production Part Approval Process (PPAP)

- First Article Inspection (FAI & FAIR)

- Last Article Inspection (LAI & LAIR)

- Initial Sample Inspection (ISI & ISIR)

- Repeatability and Reproducibility Studies (Gauge R&R)

- Measurement System Analysis (MSA)

- Statistical Process Control (SPC)

- Root cause analysis

- Independent correlation

- Quality containment and resolution

- Development of inspection procedures for new products

- Reverse engineering

Plant List

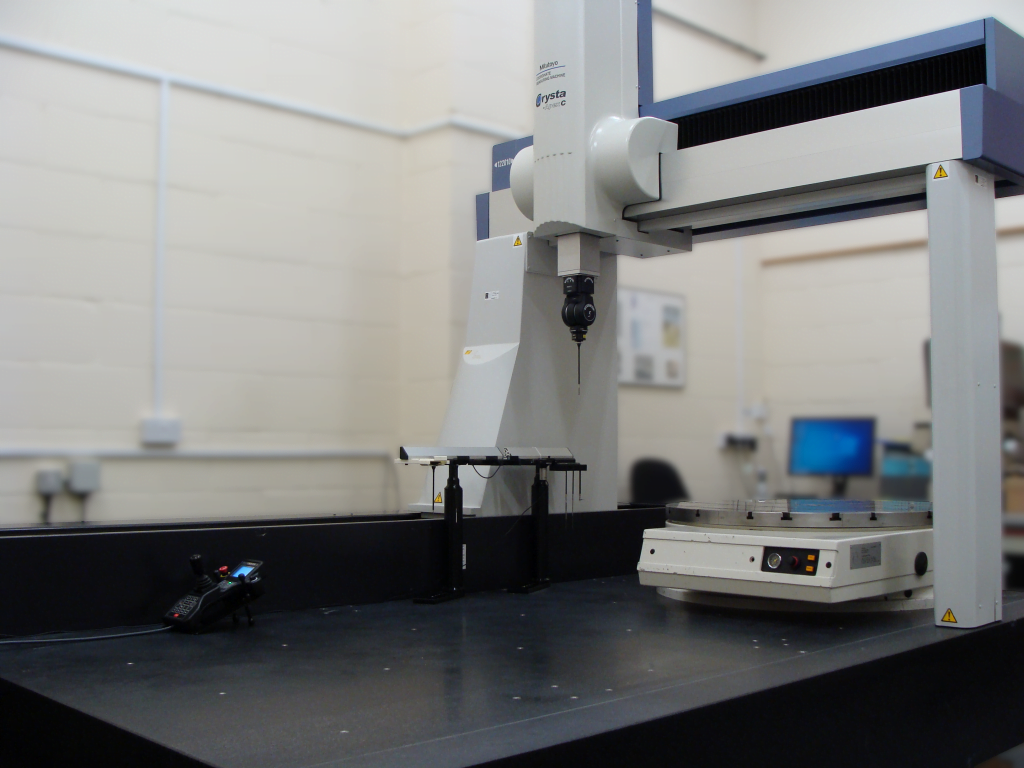

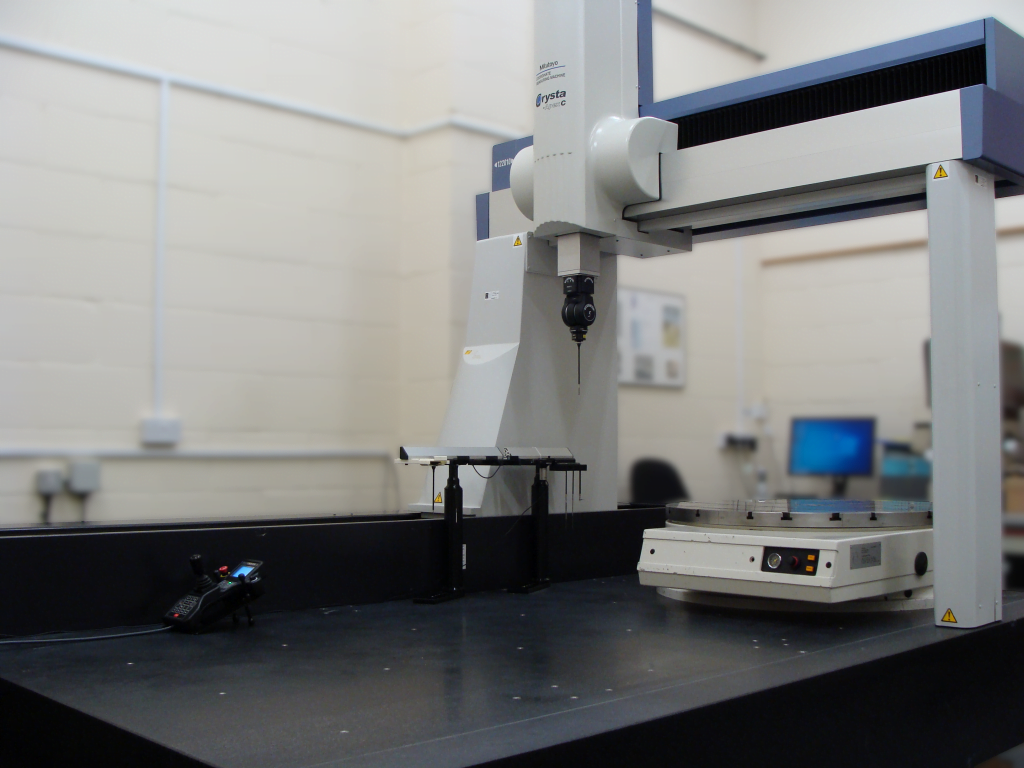

Mitutoyo Crysta Apex with REVO-2

- 1200mm x 2000mm x 1000mm working volume

- OEM UKAS Calibration

- Extremely High accuracy

- 5 Axis REVO-2 scanning head

- RSP2 and RPS3 scanning sensors

- Temperature Compensation

- Rotary Table

- Software:

- I++ UCCserver

- Renishaw Modus

- MeasureMax (via MMclient)

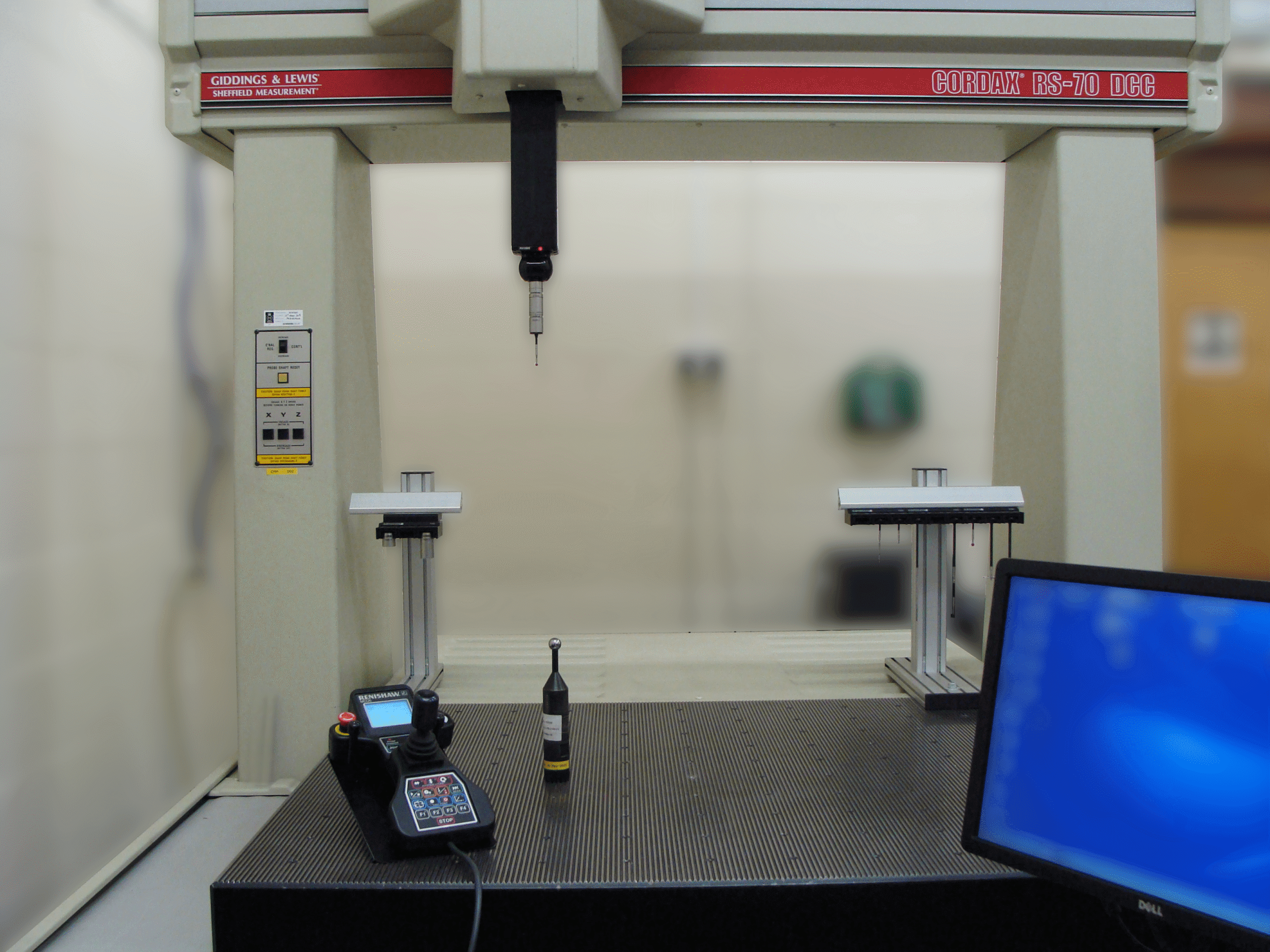

Sheffield RS-70 with PH10MQ

- 1200mm x 1000mm x 1000mm working volume

- OEM UKAS Calibration

- High accuracy

- PH10MQ head

- SP25-1, SP25-2 and SP25-3 scanning sensors

- TP20 and TP200 point measuring sensors

- Software:

- I++ UCCserver

- Renishaw Modus

- MeasureMax (via MMclient)

Over 25 Years Experience

Our precision inspection service is based on over 25 years experience gained across multiple industries, from plastic moulding manufacturing through to critical flight parts in aviation. We work with our customers start to finish to create inspection plans, design fixture assemblies, and carry out component inspection.

The Latest Technology

Investment in the latest software allows our engineers to work seamlessly with your component definition and inspection requirements, handling CAD and Drawing definitions. Our CMM’s are equipped with a range of measuring technologies including the latest Renishaw REVO-2 probe head with its unique ability to offer full 5-axis scanning. Combining all these elements allows us to deliver a high integrity inspection process with easy to understand reports.

Frequently Asked Questions

What traceability do measurements carry?

All CMM inspection work is carried out in our temperature controlled laboratory, using machines with OEM UKAS calibrations traceable to national standards. In additional to this, our managements system is ISO 9001 certified.

What size parts can you inspect?

Our largest CMM has a working volume of 1200x2000x1000 mm and we can handle up to 750 kg. We’ve successfully measured hole diameters as small as 0.4 mm.

What format will I receive my results in?

You’ll usually receive a CSV file with the measured values and a PDF report. The PDF can include deviation plots if required.

Do you offer programming services?

Yes, as well as CMM inspection services, we can also help program your machine. Whether its troubleshooting an existing program or creating a new family of programs after the purchase of a new machine.