30 Years Providing Quality Metrology Services

We know the inspection industry. We know how to meet your CMM inspection, 3D scanning, and reverse engineering requirements.

ISO 9001 certified • Rolls-Royce approved • UKAS-calibrated CMMs • Reverse Engineering• On-site or remote

Rolls Royce Approved

Certified supplier

ISO 9001:2015

Quality assured

UKAS Calibrated

Traceable CMM accuracy

Next Day Service

When you need it fast

30 Years Experience

Since 1995

About AB Technology (Newark) Ltd.

For 30 years, AB Technology has been solving precision measurement challenges for UK manufacturers.

What began in 1995 as Adrian’s vision for specialist CMM inspection services has since grown into a comprehensive metrology operation. Today, from our facility in Blidworth, we offer CMM inspection and programming, 3D scanning, reverse engineering, and first article inspection services to engineering companies worldwide.

Our temperature-controlled laboratory ensures measurement accuracy you can trust, whilst our ISO 9001:2015 certification and Rolls-Royce supplier approval demonstrate our commitment to quality. With advanced Renishaw technology, UKAS-calibrated equipment, and decades of metrology expertise, we deliver responsive, reliable precision measurement solutions across aerospace, automotive, medical devices, and defence sectors.

From rapid turnaround single measurements to ongoing production support, we’re here to help.

Our Nottinghamshire & UK-Wide Services

CMM Inspection & Programming

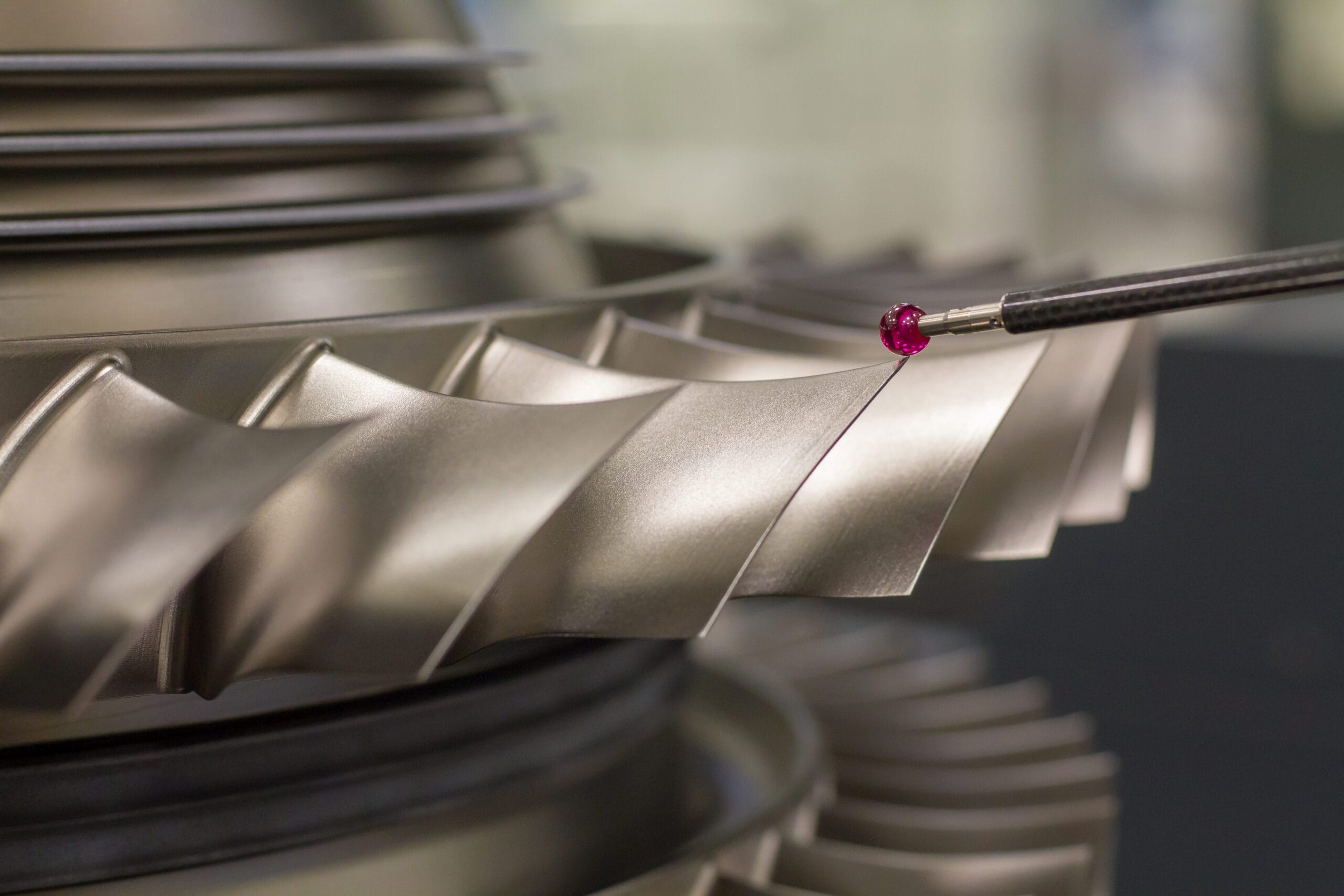

UKAS-calibrated precision measurement using advanced Renishaw REVO-2 systems. From first article inspection to full production support, we deliver traceable dimensional analysis and GD&T verification you can trust.

3D Scanning

Turn real-world objects into detailed, usable 3D models quickly and reliably. Using professional Shining 3D scanners, we capture complex geometries for reverse engineering, quality inspection, and STL creation. Available in-house or on-site at your facility.

Reverse Engineering

Convert existing objects into precise CAD models for manufacturing or design. From legacy parts without drawings to design improvements and manufacturing documentation, we deliver parametric CAD models ready for production.

Why UK Manufacturers Choose AB Technology

We deliver precision measurement solutions that save you time, reduce costs, and ensure quality compliance

Transparent Fixed-Price Quotes

Know exactly what you’ll pay upfront. No hidden fees, no surprises. Fixed pricing for defined projects or competitive hourly rates for flexible scopes.

Rapid Turnaround Times

Working to tight deadlines? Call us and we could be measuring your component the following day.

Latest Renishaw Technology

5-Axis REVO-2 head with RSP2 & RSP3 scanning probes deliver micron-level accuracy. Fully maintained and UKAS calibrated equipment you can trust.

Comprehensive Inspection Reports

Detailed dimensional analysis, GD&T verification, and first article inspection reports in PDF and CSV formats. All traceable to international standards.

On-Site & In-House Services

Can’t transport your part? We bring our portable 3D scanning equipment to you! Need high precision measurements in a temperature-controlled environment? Send your parts to our Nottinghamshire facility.

Expert Technical Support

30 years of metrology knowledge at your service. From aerospace to automotive, medical devices to defence, and of course direct to consumer.

Get Your Free Quote

Send us your requirements today. We’ll respond with a transparent, no-obligation quote.

Industries We Serve

Precision metrology services across critical UK manufacturing sectors

✈️ Aerospace & Defence

Precision measurement for turbine blades, engine components, and critical aerospace parts. Rolls-Royce approved supplier with proven expertise in aerofoil inspection and complex GD&T verification.

⚡ Energy & Power Generation

Precision measurement for gas turbine components and power-generation systems, including turbine blades, casings, rotor assemblies, and other critical rotating parts used in the energy sector

🏥 Medical Devices

Quality-critical inspection for implants, surgical instruments, and precision medical components. Full traceability measurements for regulatory compliance.

🏭 General Manufacturing

Supporting UK manufacturers across tooling, moulds, fixtures, and precision-engineered components with flexible measurement solutions tailored to your production requirements.

Real Projects, Real Results

Discover how we’ve helped UK manufacturers solve complex measurement challenges

AEROSPACE • ON-SITE 3D SCANNING • HERITAGE PRESERVATION

Inside Vulcan Bomber XL426

On-site 3D scanning inside the fuel tank of the historic Cold War bomber to enabling GKN Aerospace to manufacture modern replacement bladders for this preserved aircraft.

✓

Challenge: Scanning inside 3-metre fuel tank

✓

Solution: Handheld laser scanner with marker tracking

✓

Deliverable: Accurate 3D model of the fuel tank

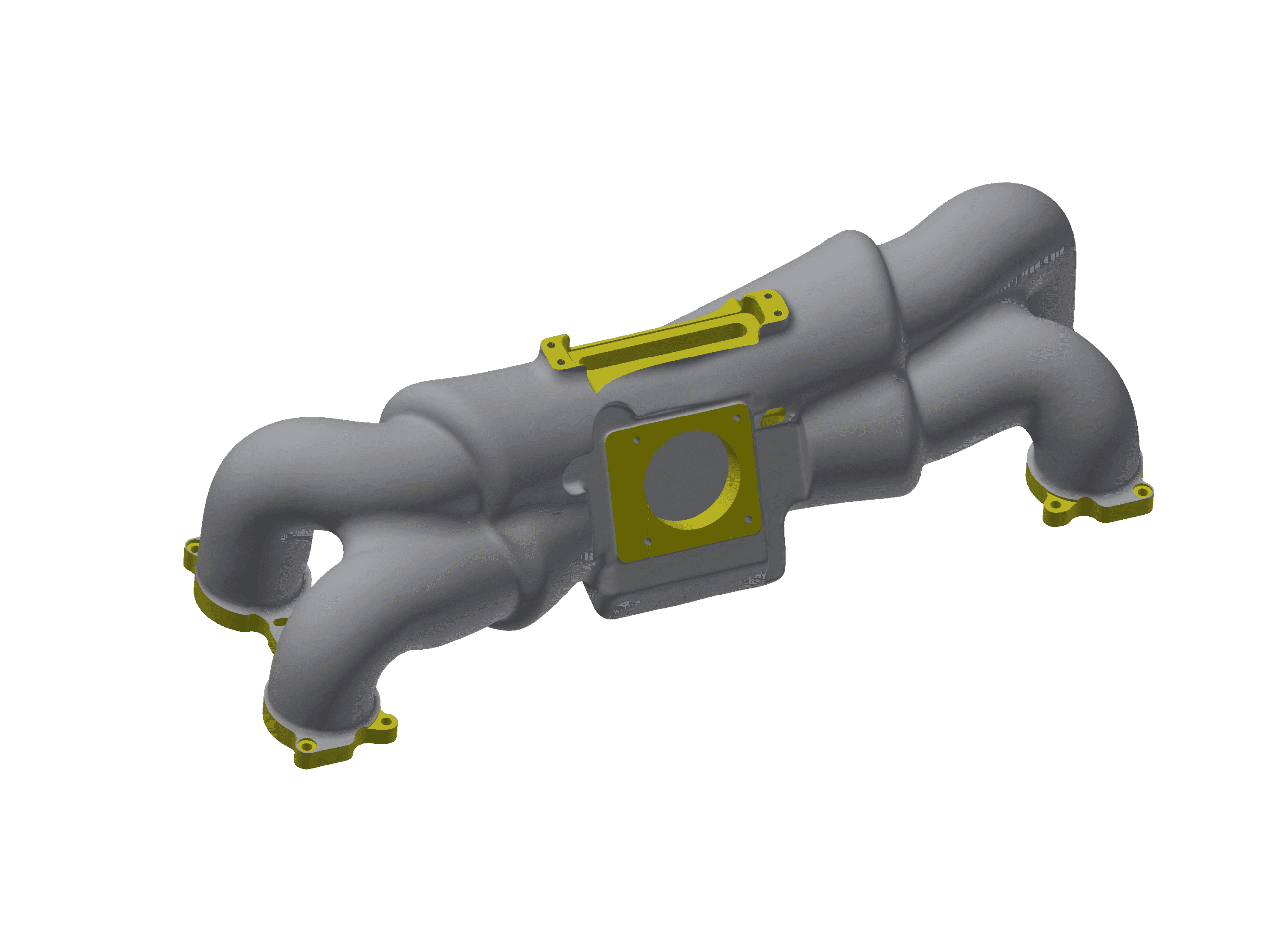

AUTOMOTIVE • 3D SCANNING • REVERSE ENGINEERING

Custom Manifold from Cosworth Casting

Combined 3D laser scanning with CMM inspection to transform a Cosworth casting into a custom Subaru Impreza inlet manifold, complete with production-ready engineering drawings.

✓

Challenge: No original CAD data for either component

✓

Solution: 3D scanning + CMM verification + CAD modelling

✓

Result: Production-ready 2D drawings with machining specs

What our clients are saying

Pricing

Our pricing is flexible and quotations can be structured to suit your project and accounting requirements.

Fixed Cost

- Free quotation.

- No obligation.

- Ideal if you have a fixed requirement.

- Suitable for jobs of all sizes.

Hourly Rate

- Free estimate.

- No obligation.

- Ideal if your requirements are variable.

- Best for on-going support.