First Article Inspection Services

Comprehensive FAI reports that verify your production process from the first part, protecting your business and your reputation.

When introducing new or modified production lines, our ISO 9001:2015 certified service ensures quality from day one with complete AS9102 and PPAP-compliant documentation.

Rolls Royce Approved

Certified CMM Inspection

ISO 9001:2015

Quality assured

UKAS Calibrated

Traceable CMM accuracy

Fast Turnaround

When you need it fast

30 Years Experience

Since 1995

Complete First Article Inspection Service

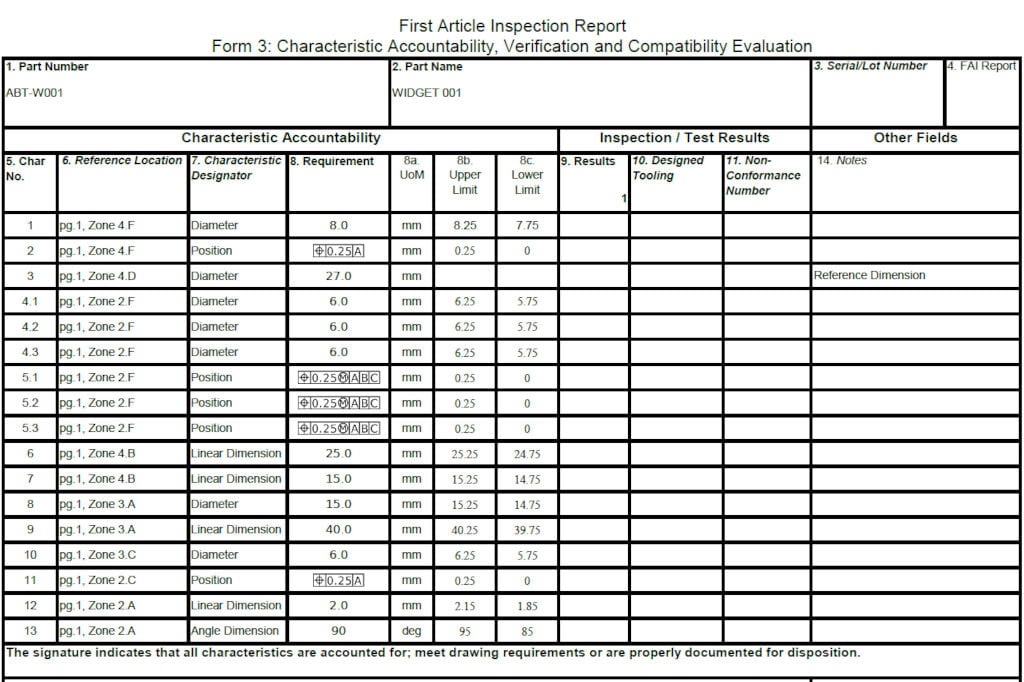

Generating and completing First Article Inspection Reports (FAIRs) is a core service at AB Technology. We offer complete FAI packages that handle every aspect of the process – from drawing preparation through to final report delivery.

Our service eliminates the complexity of FAI compliance, whether you’re working to AS9102 (aerospace), PPAP (automotive), or general manufacturing quality requirements.

Expert guidance: Our team has extensive experience supporting manufacturers through FAI requirements.

Full-Service Package Includes:

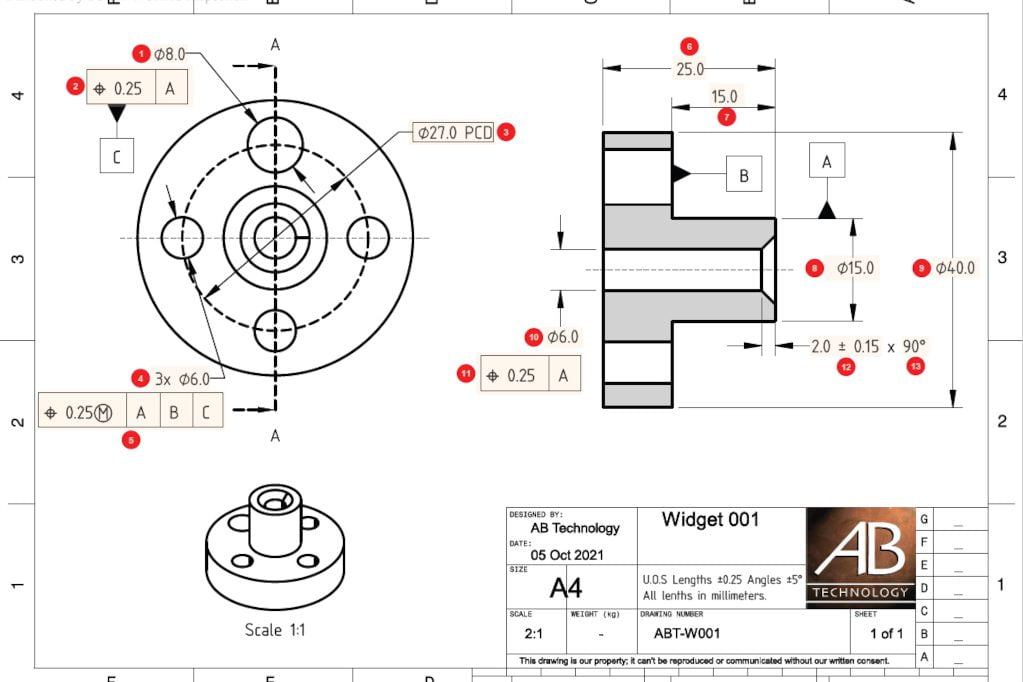

Drawing & Form 3 preparation – Ballooned engineering drawings with characteristic numbering.

Dimensional inspection – Complete measurement using CMM, optical projector, and hand tools.

Report completion – Populated AS9102 Form 3 (or equivalent) detailing all requirements, results, tolerances etc.

Supporting documentation – CSV data files and PDF reports as required for your records.

Need FAI support? We make the process straightforward.

If your customer has requested First Article Inspection, contact us to discuss your requirements. We’ll guide you through the process and provide a clear quote.

When Do You Need a First Article Inspection?

First Article Inspection Reports verify that your production process can consistently manufacture parts to specification. FAI is typically required after process development is complete, before full production begins.

An FAI report is often a customer requirement determined by quality management standards such as PPAP (automotive) or AS9100 (aerospace). The report provides documented evidence that your process produces conforming parts, giving both you and your customer confidence.

FAI Required When:

- New production process – After finalising your manufacturing setup

- Process changes – Any modification affecting form, fit, or function:

- Manufacturing method changes

- Tooling modifications or replacements

- Supplier or material changes

- Production location changes

- Inspection method updates

- Engineering changes – Drawing revisions requiring revalidation

- Production resumption – After extended shutdown periods (customer dependent)

Industry standards: FAI requirements are defined in AS9102 (aerospace), PPAP manuals (automotive), and ISO 9001 quality procedures. We’re familiar with all major standards and customer-specific requirements.

Our FAI Process

1. Document Review & Planning

We review your engineering drawings and specifications to identify all characteristics requiring verification. If needed, we create ballooned drawings with systematic numbering for the Form 3 report.

2. Measurement Execution

We inspect your first article sample using appropriate methods: Renishaw REVO-2 CMM, optical projection for small features, and calibrated hand tools.

3. Report Completion

We populate the Form 3 with all measured results, calculated values, and conformance statements. You receive the complete FAIR package ready for customer submission, plus supporting CSV/PDF data files.

Measurement Methods for First Article Inspection

We select the optimal measurement method for each characteristic based on feature type, tolerance requirements, and accessibility. All equipment is UKAS calibrated annually.

CMM Inspection

Equipment: Renishaw REVO-2 5-axis systems

Best for: Dimensional accuracy, GD&T

Accuracy: Up to 0.003mm

Optical Projection

Magnification: Up to 50x for detailed inspection

Best for: Small features, 2D profiles

Applications: Small chamfers & radii

Calibrated Hand Tools

Equipment: Micrometres, verniers, gauge blocks

Best for: Basic dimensions

Typical use: Rapid overchecks

Quality Assurance You Can Trust

All First Article Inspection work is performed in our temperature-controlled (20 °C ± 1 °C) metrology laboratory using UKAS-calibrated CMMs. Our quality management system is ISO 9001:2015 certified through ISOQAR.

Certificate Number: 3001

Last Article Inspection (LAI)

When modifying an existing production process that requires a new FAIR, we strongly recommend completing a Last Article Inspection report before making changes.

Last Article Inspection follows the same process as FAI but measures the final part produced under the current process. This creates definitive before-and-after documentation, proving that your modifications maintain (or improve) part quality.

Why LAI Matters:

- Quantifiable baseline – Documents current process capability before changes

- Change validation – Proves new process maintains conformance

- Risk mitigation – Identifies if changes introduce variation

- Customer confidence – Shows due diligence in process control

Best practice: Complete LAI and FAI as a paired service when making process changes. This provides complete traceability and demonstrates continuous quality control.

Ready to Complete Your First Article Inspection?

Contact us for a free, no-obligation quote. We’ll review your requirements and provide clear pricing and turnaround times.

ISO 9001:2015 Certified • Rolls-Royce Approved • UKAS Calibrated CMM Equipment