CMM Programming Services

Expert CMM programming combining knowledge and skills to produce efficient, robust programs for your measurement needs

From One-Off Inspections to Volume Production

ABT’s subcontract CMM programming service combines expert knowledge and part programming skills to produce efficient and robust CMM programs. From one-off inspections to volume production, our CMM programming service will deliver.

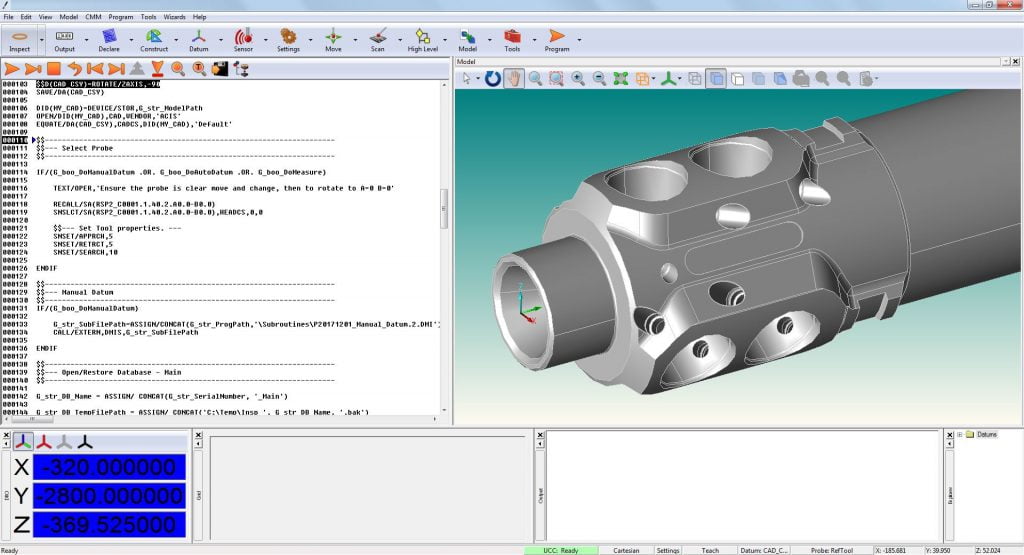

We are experts at utilising Renishaw PH20, REVO and REVO-2 systems to measure any part. Programming onsite or remotely in the DMIS-based Modus software, our engineers will write an efficient and robust CMM program.

Our offline CMM programming and simulation software enables us to create inspection programs from your CAD model or drawing prior to your part being available. Once your physical component becomes available, the CMM measurement program is ready to go live, meaning you benefit from a reduced lead-time and enabling you to maximise your productivity.

Our CMM Programming Software Expertise

Renishaw Modus

Primary Software Platform

DMIS-based programming with full CAD integration. Expertise in Renishaw PH20, REVO and REVO-2 systems. Includes UCC Server for remote programming capability.

Hexagon Quindos

Advanced Programming

Quindos 7 programming with 3D CAD model integration for complex geometries and advanced measurement strategies.

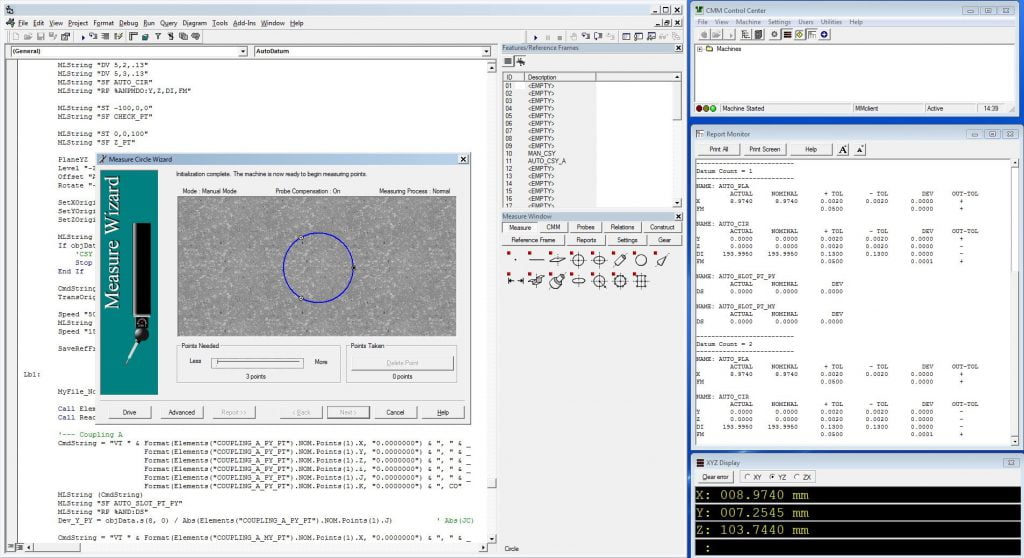

MeasureMax

Sheffield Systems

Visual Basic programming for Sheffield CMM systems. Flexible programming environment for custom measurement routines.

Additional Programming Capabilities

- LK Camio

- Taylor Hobson Ultra, Talysurf CCI & PGI Matrix

- DMIS & I++ based software

Use another programming language? First and foremost, we are engineers with a passion for problem-solving. If we can help, we will. Challenge us!

Quality Assured CMM Programming

Our CMM programs are validated on UKAS calibrated equipment in our temperature controlled laboratory. Our programming processes are ISO 9001:2015 certified, ensuring consistent quality and traceability from program development through to delivery.

Certified since 2002 • Rolls Royce approved supplier since 2005 • UKAS accredited measurements

Certificate Number: 3001

What You Get With Our CMM Programming

⚡

Efficient Programs

Optimized measurement routines that minimize cycle time while maintaining accuracy

🔧

Easy to Maintain

Well-structured programs your operators can maintain and upgrade – no tricks to keep you tied

📊

CSV Reporting

CSV reporting included as standard – essential for SPC and tracking results

💻

Offline Programming

Programs created from CAD before parts arrive – reduced lead-time and maximized productivity

📄

Complete Documentation

Measurement databases, automatic PDF reports, and visual plots of scanned data

✅

Full Validation

Options for Gauge R&R or MSA to demonstrate program robustness and quality

Our CMM Programming Process

1

Requirements Review

We review your drawings, CAD models, and measurement requirements to understand the scope

2

Program Development

Offline programming and simulation creates efficient, robust programs ready before your parts arrive

3

Validation & Handover

Prove out at our facility or yours, with optional Gauge R&R to demonstrate program quality

Frequently Asked Questions

Which CMM systems can you program for?

We specialize in Renishaw systems (PH20, REVO, REVO-2) using Modus software and Sheffield systems using MeasureMax. We also work with Quindos 7, LK Camio, Taylor Hobson systems, and any DMIS or I++ based software.

Can you program remotely?

Yes! We run Modus and MesaureMax internally and can uses these to create your programs remotely. Offline programming allows us to create programs before parts are available, then prove them out remotely or during an on-site visit.

How long does it take to create a CMM program?

Timeline depends on part complexity and measurement requirements. Simple parts can be programmed in days, while complex assemblies may take 1-2 weeks. With offline programming, we can have programs ready before your parts arrive.

Do you provide operator training?

We create programs that are well-structured and easy to maintain so your operators can modify them. We can provide handover training and documentation to ensure your team can work with the programs effectively.

Ready to Discuss Your CMM Programming Needs?

From one-off inspections to volume production programs, we combine decades of experience with the latest programming techniques