3D Scanning Portfolio

Here’s a portfolio of parts we’ve recently measured using one of our 3D Scanning Systems. These are a combination of parts that our customers have agreed to us showcasing and parts that we have scanned just for fun and to demonstrate our scanning capabilities.

If you’d like to suggest something else we could scan, or to see if we could scan your parts, just get in touch via our Contact Us page.

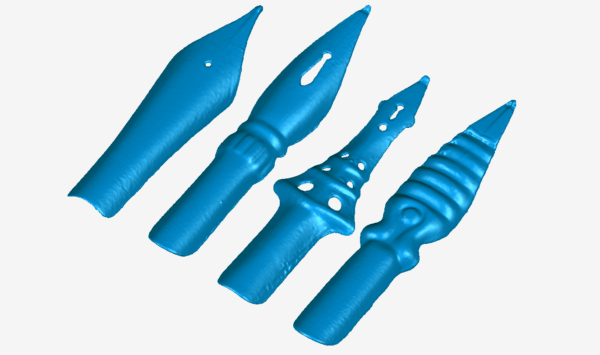

Small things

Small objects are usually scanned using our structured light scanner and turntable. Together they can scan parts as small as 1-2 centimetres with great detail.

Small Object Case Studies

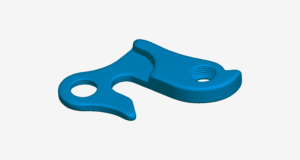

Enabling CAD-based Product Design through Reverse Engineering a Bicycle Hanger

Read more: Enabling CAD-based Product Design through Reverse Engineering a Bicycle HangerOur customer, a manufacturer of specialist bicycles, approached us with a challenge. They needed to fully model their bikes in CAD, but they lacked CAD models for the bought-out components. Specifically, they needed a CAD model for a bicycle hanger.

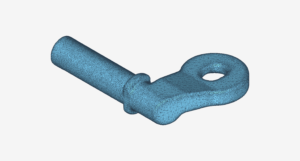

Combining 3D Scanning and Printing To Save A Door

Read more: Combining 3D Scanning and Printing To Save A DoorOur customer required what should have been a simple replacement part for their door. However the design had changed since they installed the original door latch, meaning the current version is incompatible with older versions. Read how we helped avert the need to replace the whole door using 3D Scanning.

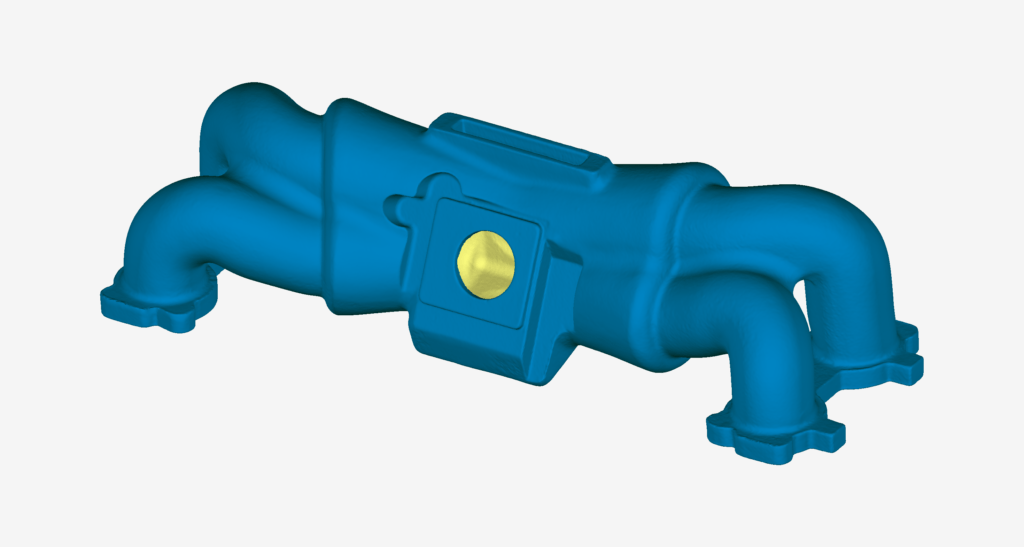

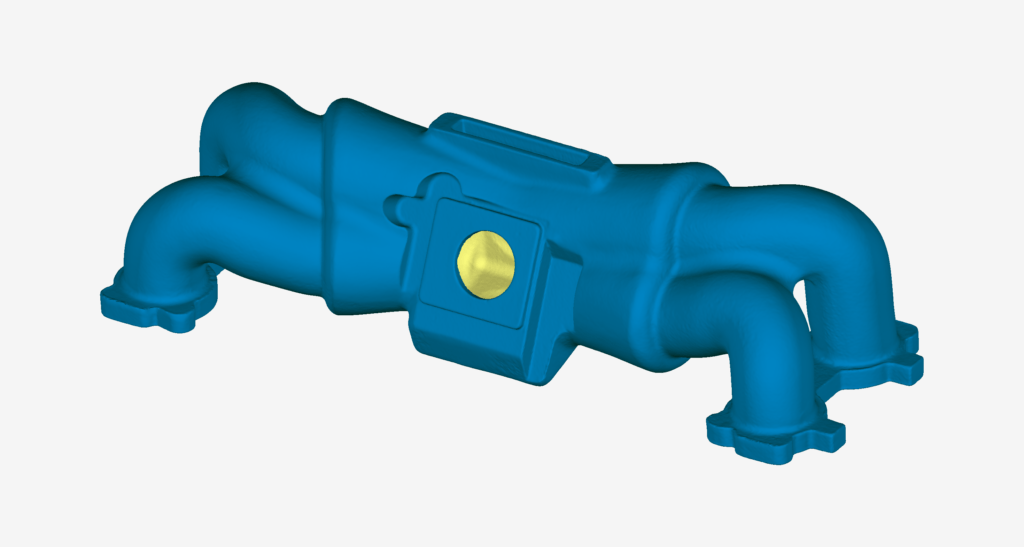

Castings

We have scanned many castings for a range of industries including the agricultural & automotive industry. Here’s an inlet manifold casting we scanned using out handheld scanning system.

A Banana

A light-hearted test to assess the colour mapping capabilities of our structured light scanner. We fully 3D scanned a banana including colour textures. Check out the model to see the results.

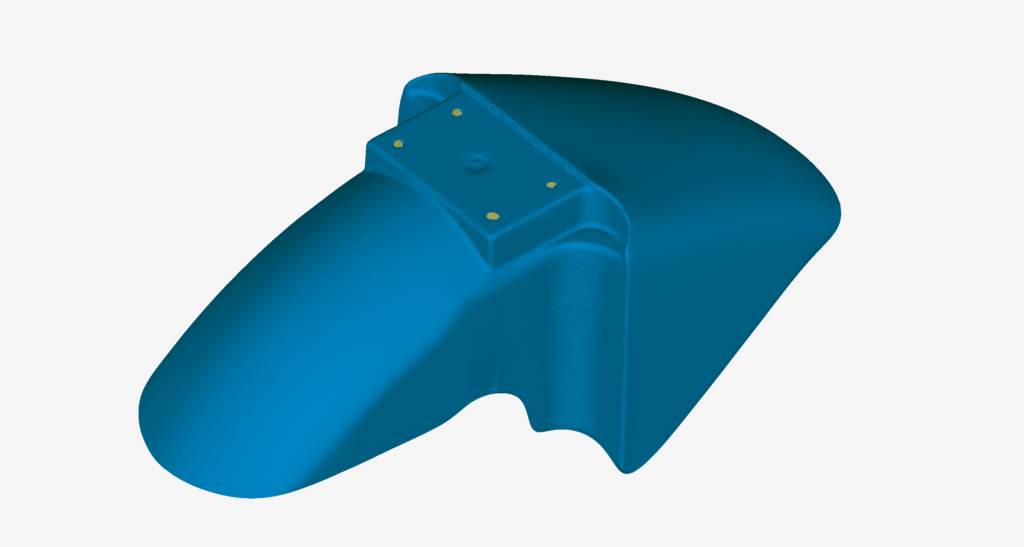

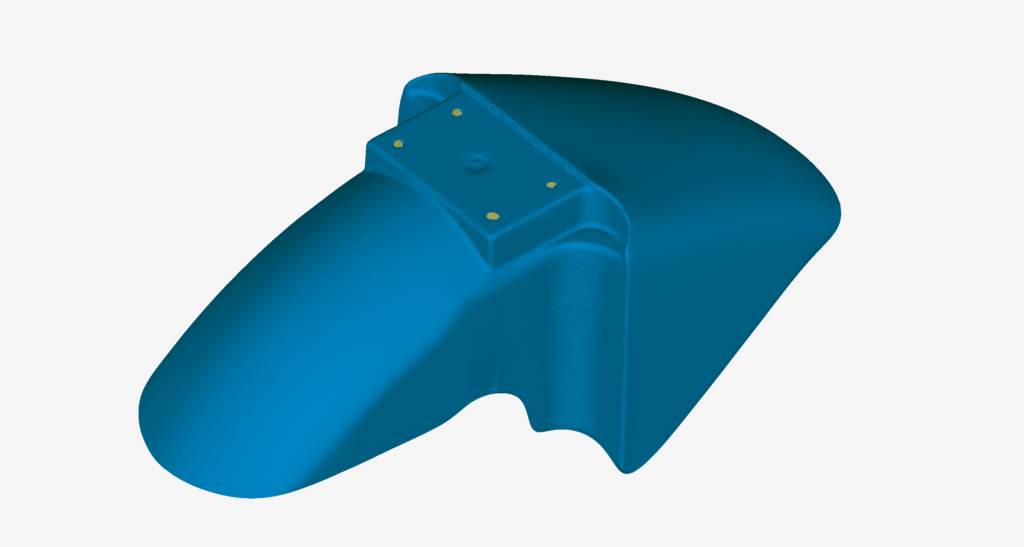

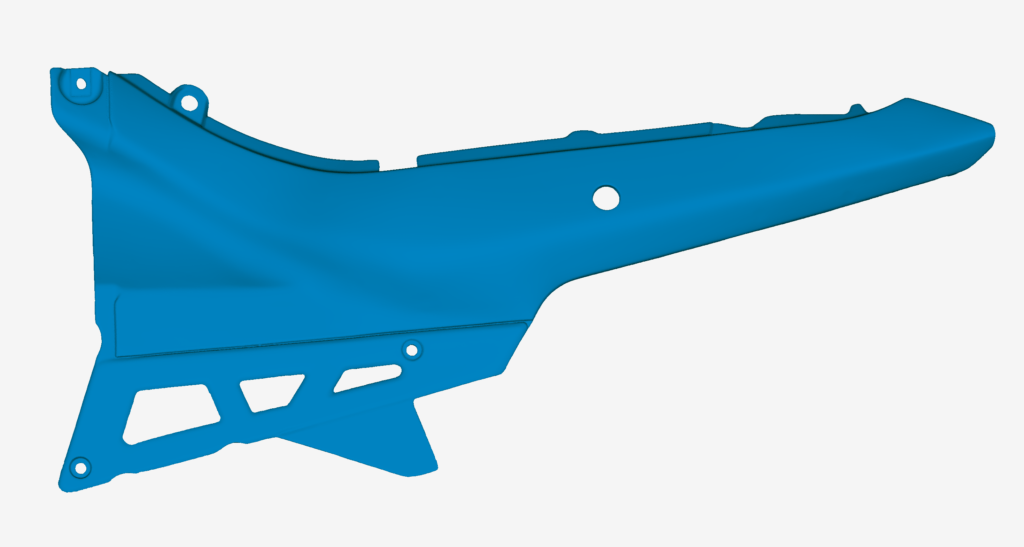

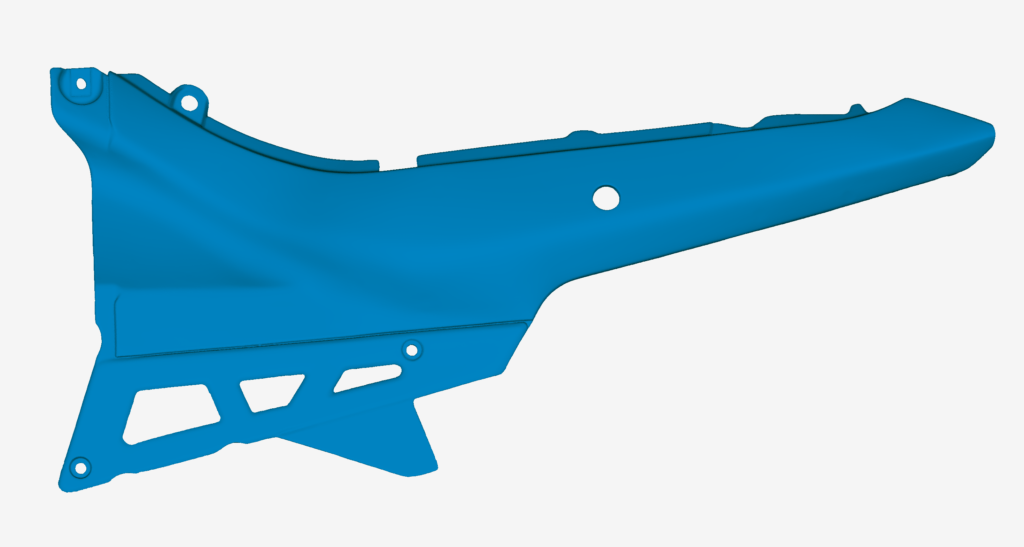

Motorcycle fairing (bodywork) & helmet

Scanned using our handheld scanner in either structured light or laser scanning mode, the front fender and rear side panel fairing from a Suzuki GSX600F and a full face motorcycle helmet including visor.

Want us to scan your part?

For a free no obligation quote

About Us

AB Technology started out as an independent CMM Inspection & Programming company based near Nottingham, UK. Over the last 30 years, we have expanded our services to include 3D scanning and reverse engineering, serving customers of all sizes, across an array of industry sectors, both domestically and internationally.

Key Links

Contact Us

AB Technology (Newark) Ltd.

Unit 8, Crewe Close

Blidworth

Nottinghamshire

NG21 0TA

United Kingdom