Explore AB Technology’s Core Services.

Precision CMM inspection & programming, 3D scanning, and reverse engineering.

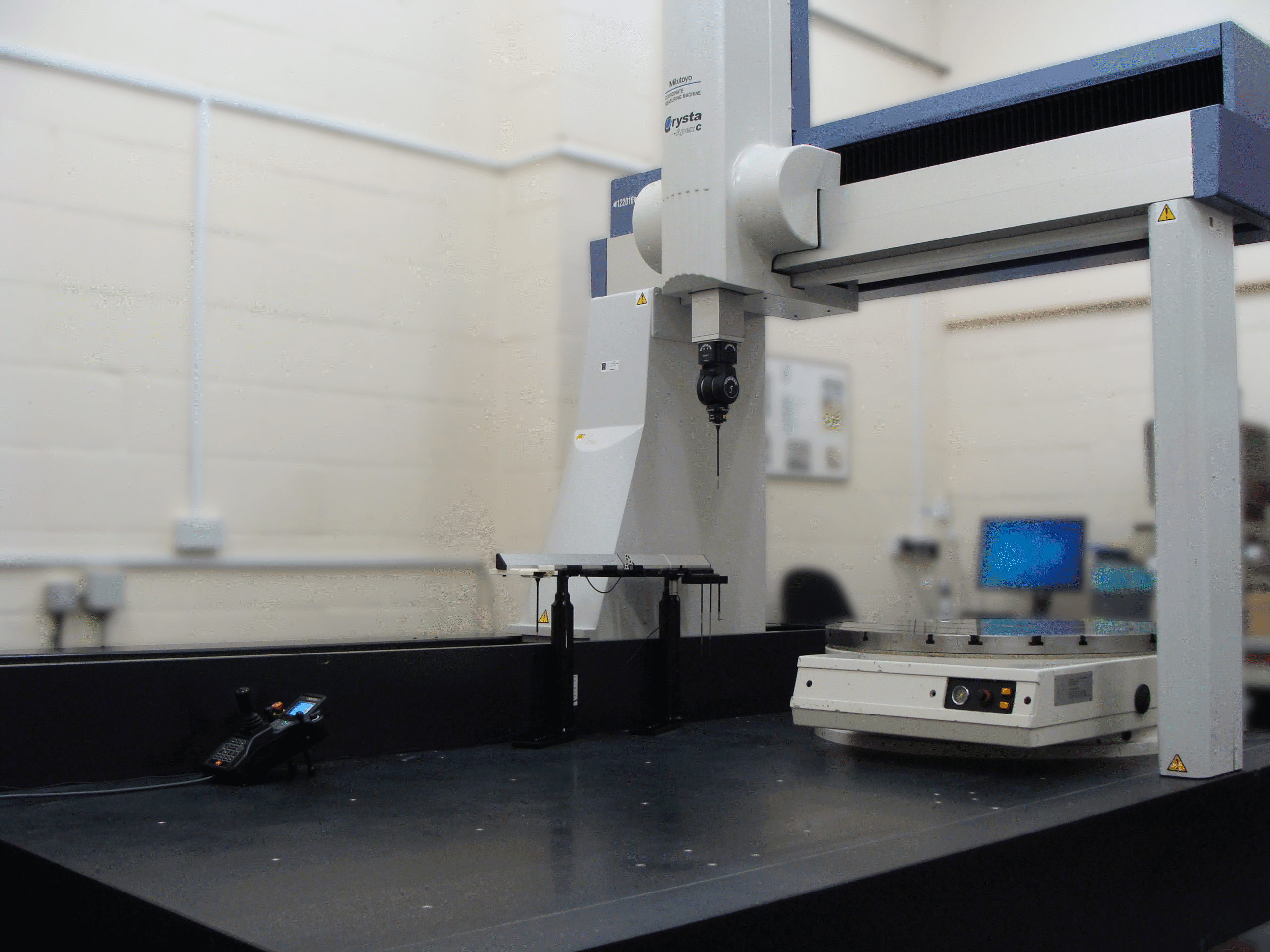

CMM Inspection & Programming Services

UKAS-accredited CMM inspection, fully traceable to international standards. We inspect your parts in our lab, from one-off First Article Inspections to volume production. We also provide expert CMM programming, enabling you to run inspections efficiently on your own machine.

- High Accuracy Machines

- OEM UKAS Certifications

- Temperature Controlled Environment

- REVO-2 & PH10MQ Probe Heads

- Modus & MeasureMax Support

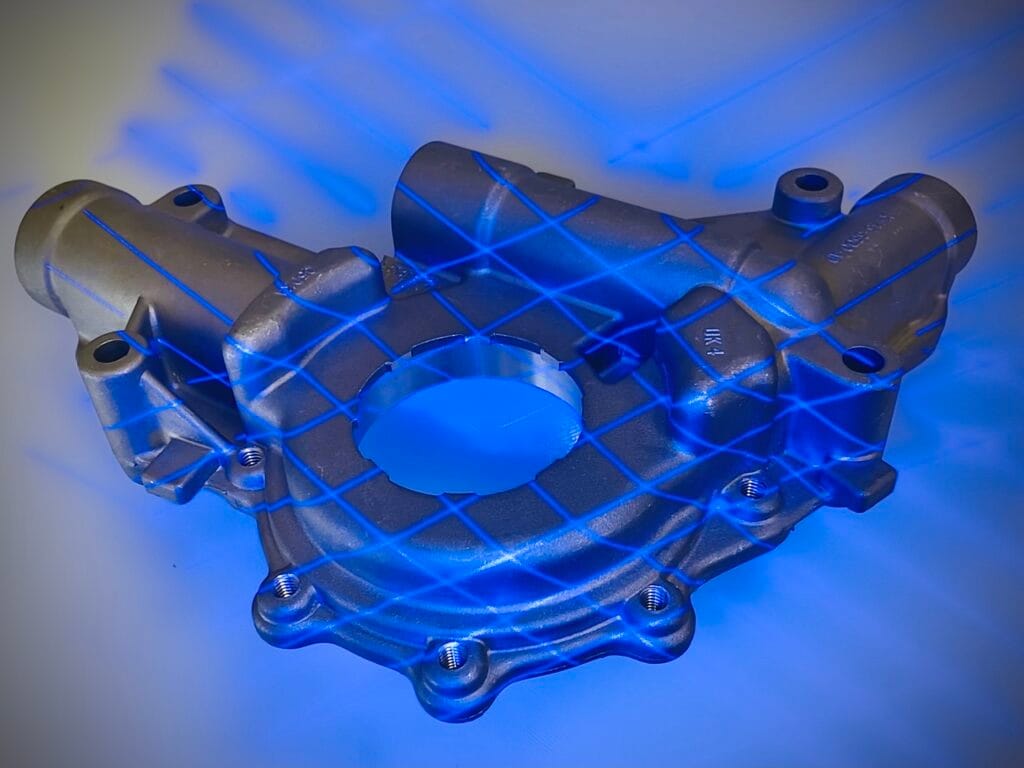

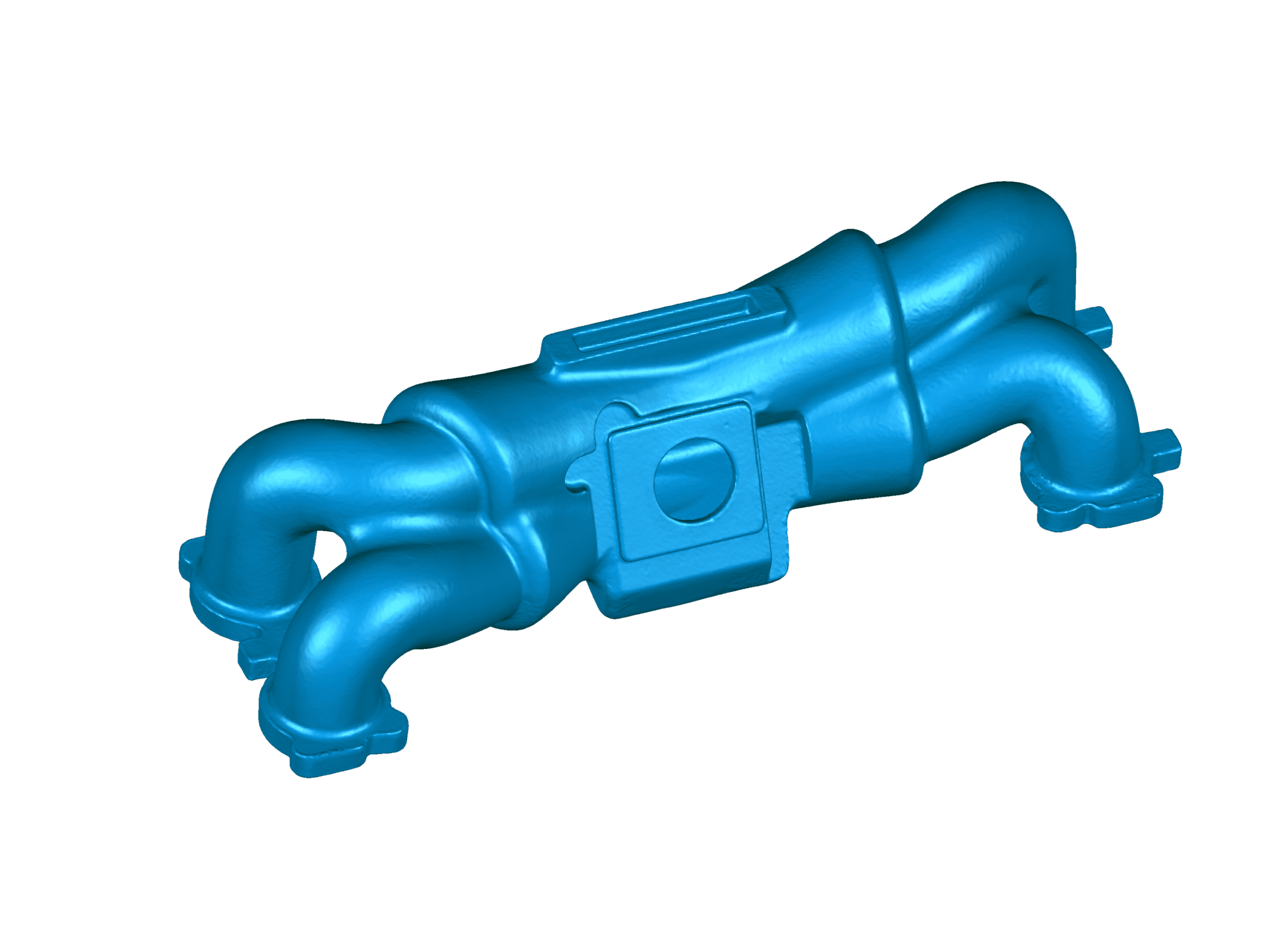

3D Scanning Services

Non-contact 3D scanning to capture accurate digital models of your parts. Create 3D meshes for analysis, 3D printing, or reverse engineering. Available in-house in Nottinghamshire or on-site for large, fragile, or immovable items.

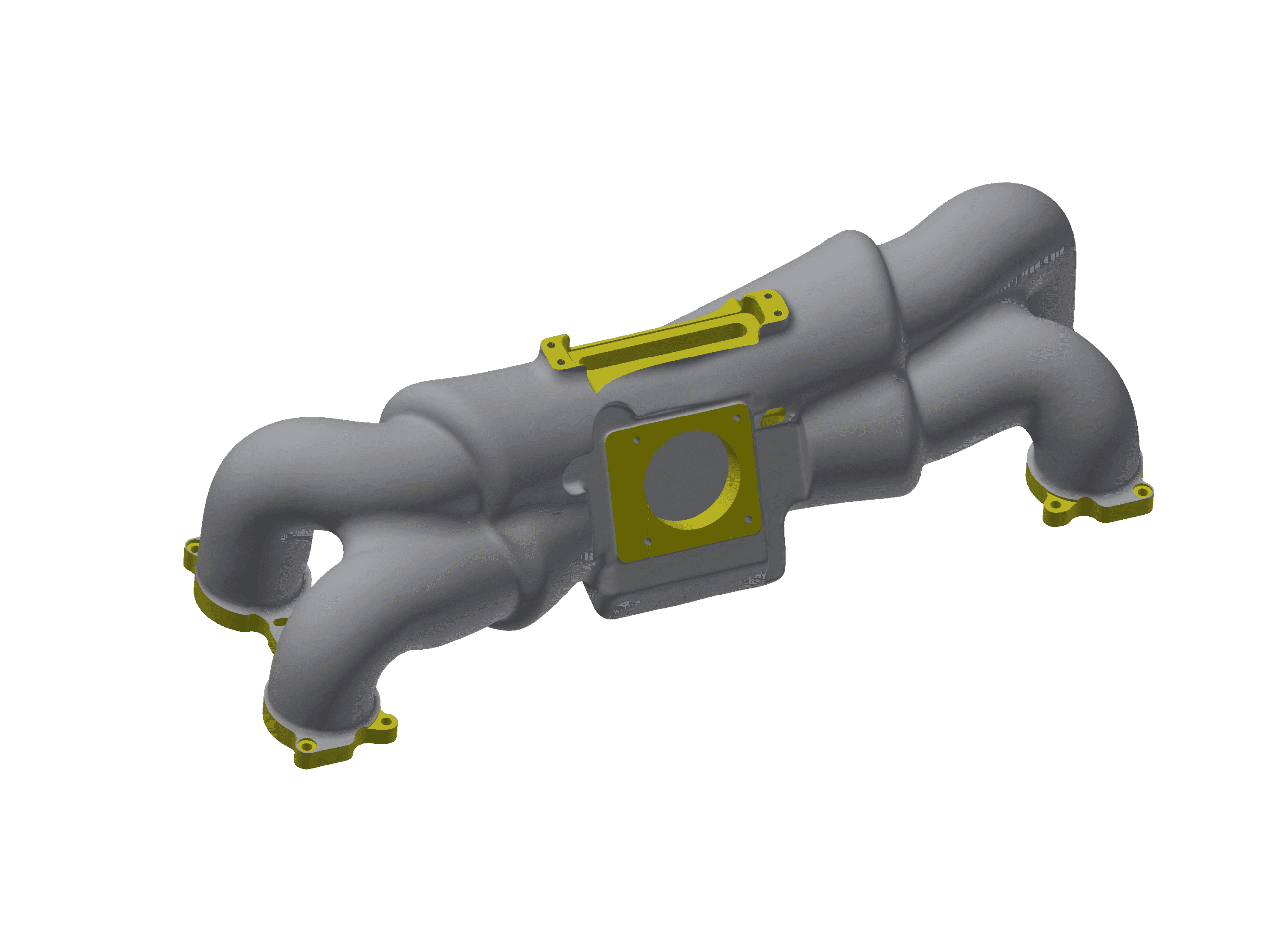

Reverse Engineering Services

Our reverse engineering service captures detailed measurement data and translates it into editable 3D CAD models that keep your design intent and manufacturability intact.

Ideal for replacing lost drawings, modernising legacy components, or digitising a prototype for further design enhancements.

You might also be interested in…

First Article Inspection Report

We will use the most appropriate measurement techniques to produce an FAI report for your part.

- Ballooned Drawing

- Full Dimensional Inspection

- AS9100 Report

Metrology-as-a-Service

Scalable inspection services tailored to your organisations requirements without capital investment.

- CMM Inspection

- 3D Scanning

- Low or High Production Volumes

2D Drawing to 3D Model

Modernise your hand-drawn legacy drawings to unlock modern CNC manufacturing for your parts.

- 3D CAD Model

- 2D PDF Drawings

- Reverse Engineer Missing Features

MMClient I++ Virtual Controller

Enables MeasureMax software to run on Renishaw’s UCCserver I++ Controller.

- Keep your legacy programs

- Provide path to modern hardware

- Gives you options for moving forward

Full Plant List

View the equipment we have ready and available to service your parts.

- UKAS Certified CMMs

- Professional 3D Scanners

- Calibrated Hand Tools