Non-contact Inspection Services

Full surface non-contact scanning service providing detailed dimensional inspection analysis.

Non-contact Inspection

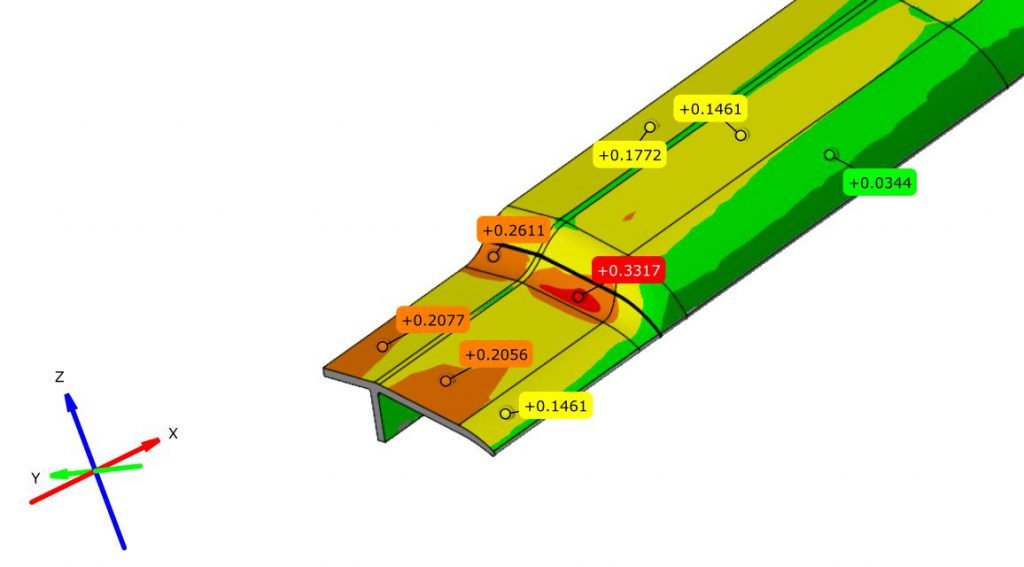

Non-contact dimensional inspection using 3D scanning technology is a cost-effective way to accurately achieve full surface inspection of your product. From small plastic mouldings to full size gas turbine engine components, we can prove easy to understand inspection reports tailored to your requirements.

Once your product’s size, shape geometry has been captured and digitised using our non-contact scanning service, we can compare the result to your 3D CAD model to produce detailed colour map deviations reports and a full dimensional inspection report.

Fully flexible service

AB Technology is uniquely positioned to be able to offer both contact and non-contact inspection services, meaning our capability for dimensional inspection is near limitless. Our hybrid inspection capability means we can take all the strengths of both traditional CMM contact measurement and the latest non-contact inspection techniques and combine them into a unique service.

Advanced defect detection

Non-contact inspection is a highly efficient method of ensuring you only ship high quality confirming products. Capable of capturing large amounts of data in a short space of time, it is perfect for small defect detection on large surfaces.

To find out more

We are here to help

About Us

AB Technology started out as an independent CMM Inspection & Programming company based near Nottingham, UK. Over the last 30 years, we have expanded our services to include 3D scanning and reverse engineering, serving customers of all sizes, across an array of industry sectors, both domestically and internationally.

Key Links

Contact Us

AB Technology (Newark) Ltd.

Unit 8, Crewe Close

Blidworth

Nottinghamshire

NG21 0TA

United Kingdom