3D Scanning Portfolio

Here’s a portfolio of parts we’ve measured using one of our 3D Scanning Systems. These are a combination of parts that our customers have agreed to us showcasing and parts that we have scanned just for fun and to demonstrate our scanning capabilities.

If you’d like to suggest something else we could scan, or to see if we could scan your parts, just get in touch via our Contact Us page.

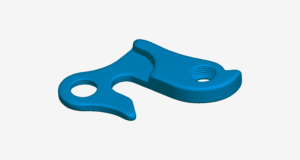

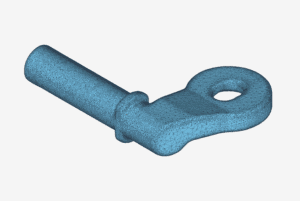

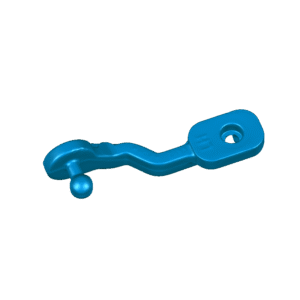

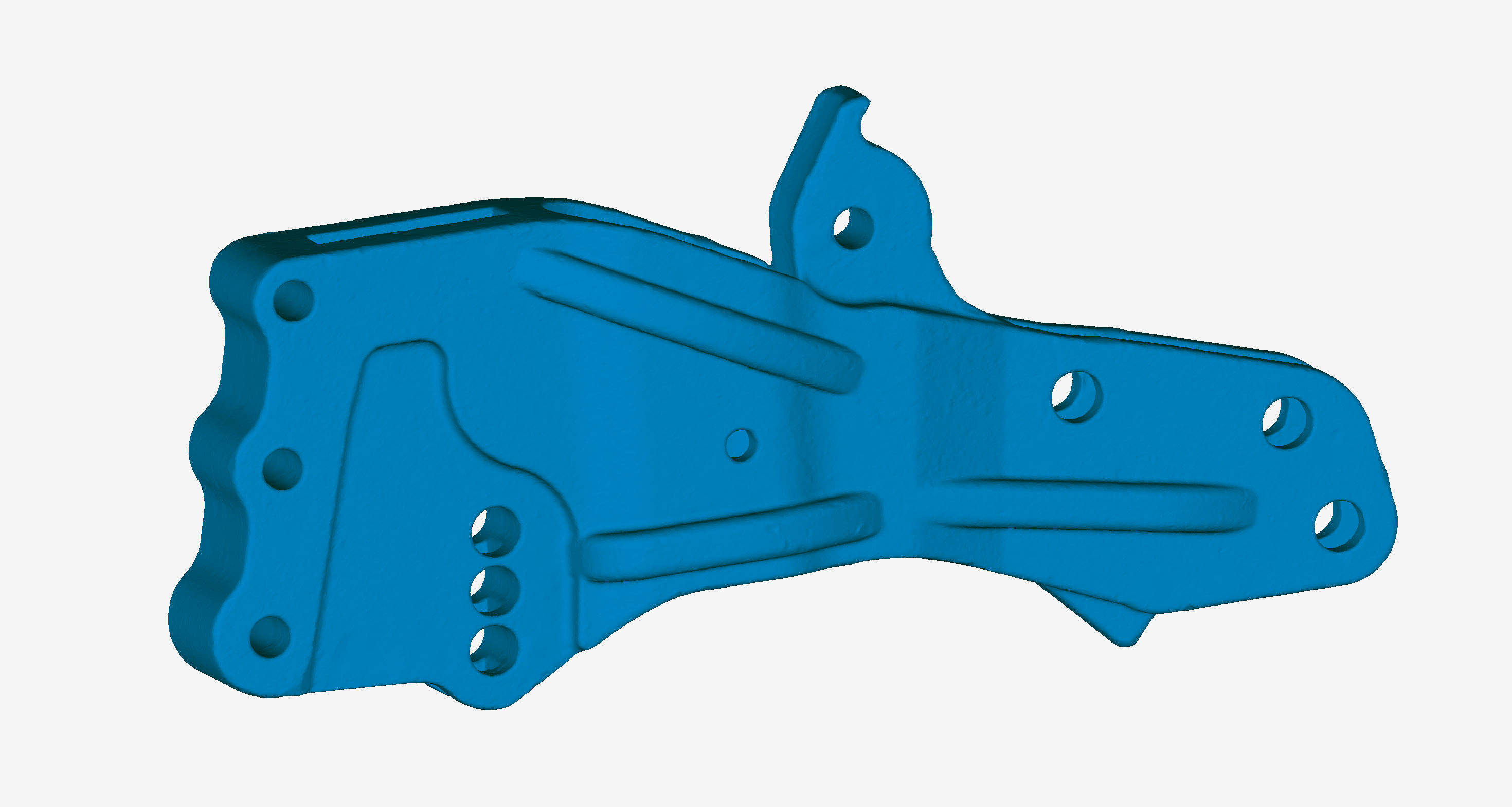

Small Component Scanning

Our structured light scanner captures components as small as 1-2 cm up to 20-30 cm with resolutions down to 0.035 mm. Perfect for scanning small objects with create detail, this scanner excels at sharp corners. These scans are typically used for parts that require reverse engineering or 3D printing.

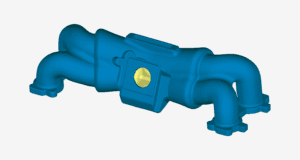

Castings

We have used our handheld laser scanner to digitise many castings for a range of industries including the agricultural & automotive industry. Check out our case study on the inlet manifold casting we scanned using out handheld scanning system as part of a customer reverse engineering project.

A Banana

A light-hearted test to demonstrate the colour mapping capabilities of our structured light scanner. We fully 3D scanned a banana including colour textures. Check out the model to see the results.

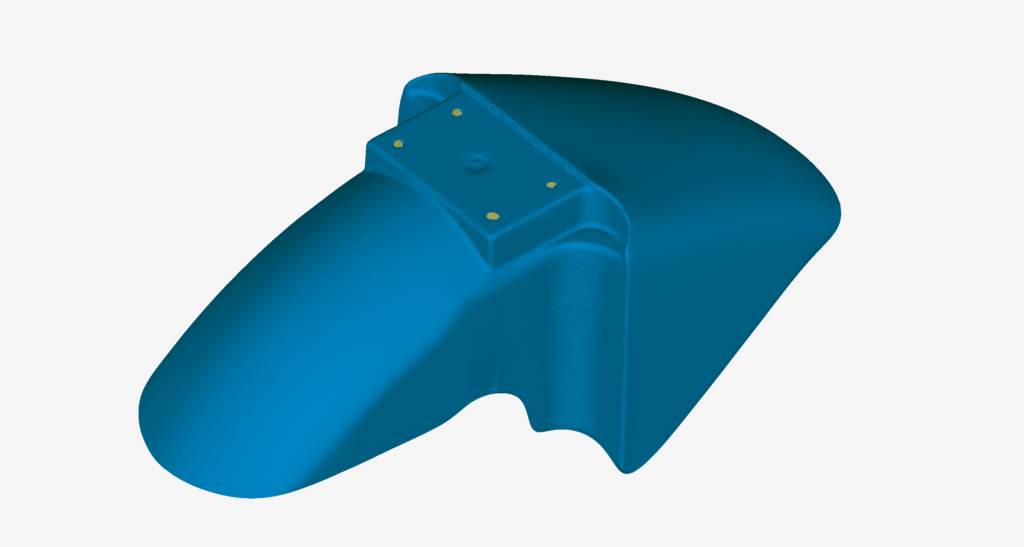

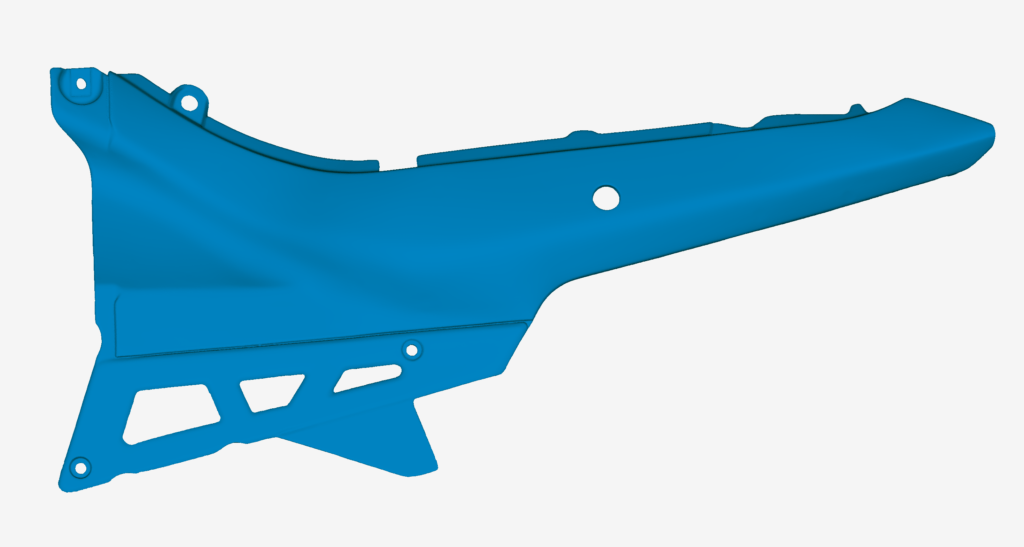

Motorcycle Fairing (Bodywork) & Helmet

Large plastic parts scanned using our handheld system in structured light or laser mode. Front fender and rear side panel from a Suzuki GSX600F, plus a full-face motorcycle helmet including visor – typical examples for aftermarket development or custom applications.

Custom Vehicle Components & Body Work

We regularly 3D scan automotive components for custom jobs ranging from individual parts to full body sections. Using our handheld scanners, we can capture complex geometry on-site or in our lab, producing accurate meshes for reverse engineering or as reference geometry for new designs that must fit to existing parts. Below are some examples of on-site 3D scanning, including custom alloy wheels and a fibreglass body.

Need Your Parts Scanned?

From micro-components to complete assemblies – reverse engineering, inspection, or manufacturing preparation