3D Scan To CAD

Our 3D Scan To CAD Services

At AB Technology, our Scan to CAD services can provide you with both STEP and parametric solid models for your physical part. Our one stop service covers all aspects of the process, from 3D scanning thought to delivery of the final CAD model. This process is ideal for reverse engineering or recreating legacy parts, and has the key advantage of allowing easy editing of the resulting CAD model. With our advanced technology and experienced engineers, we can accurately capture the design intent of your part and create a CAD model that meets your requirements.

Want to see examples of our work?

Check out some of our reverse engineering case studies below for real examples of project we’ve completed for our customers.

How We Reverse Engineered a Casting into a Custom Manifold

Read more: How We Reverse Engineered a Casting into a Custom ManifoldOur customer, a prominent player in the automotive aftermarket industry, approached us with a specific challenge: they needed a solution for creating a custom machined Subaru Impreza High Volume Inlet Manifold from a Cosworth Intake Manifold Casting.

Enabling CAD-based Product Design through Reverse Engineering a Bicycle Hanger

Read more: Enabling CAD-based Product Design through Reverse Engineering a Bicycle HangerOur customer, a manufacturer of specialist bicycles, approached us with a challenge. They needed to fully model their bikes in CAD, but they lacked CAD models for the bought-out components. Specifically, they needed a CAD model for a bicycle hanger.

How does Scan to CAD work?

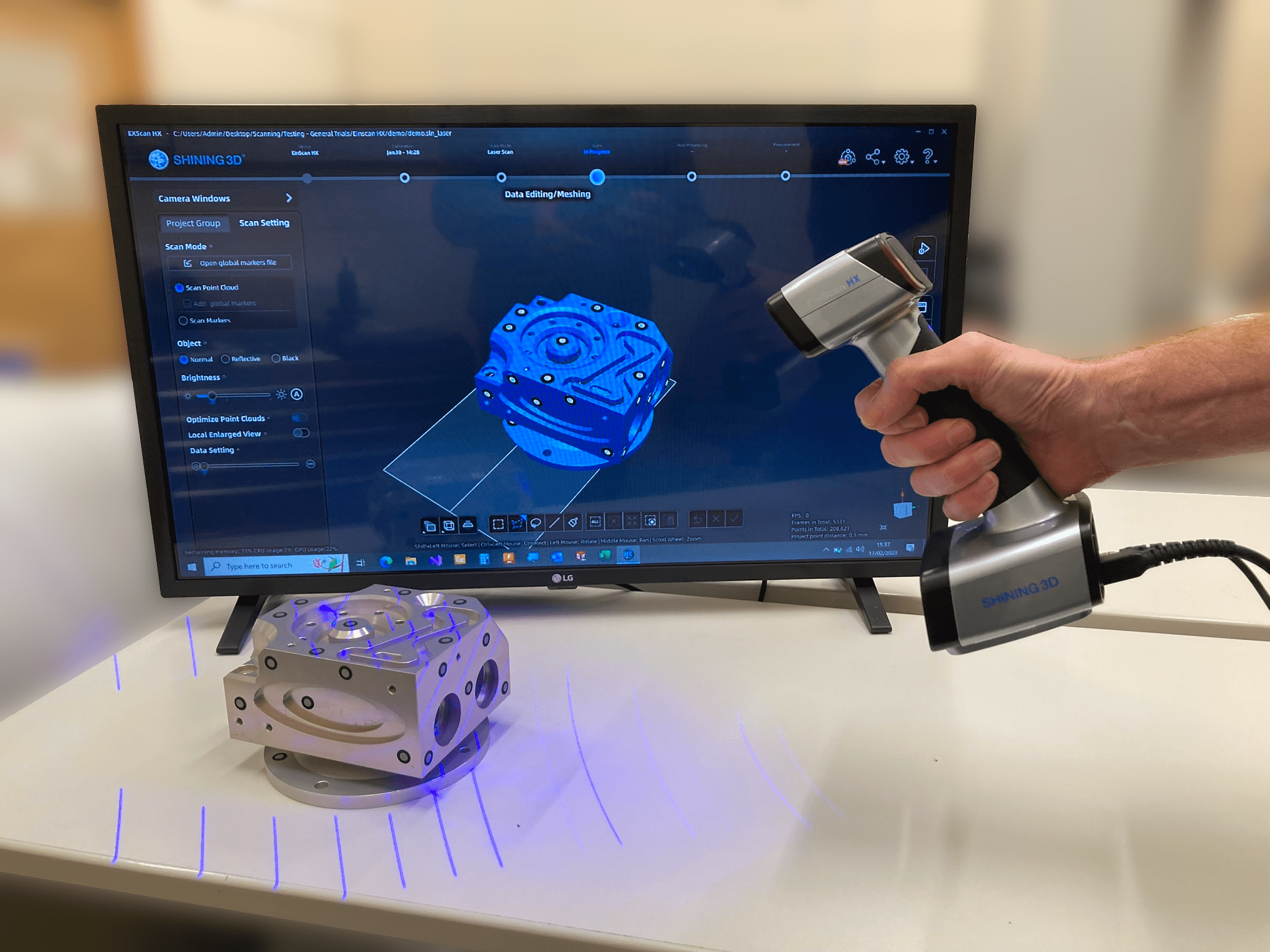

Our Scan to CAD service starts with a high-resolution 3D scan of your object using our advanced 3D scanning equipment. The scan captures every detail of the object’s shape, allowing us to create a detailed mesh that serves as the basis for the CAD model. We then use specialised software to convert the mesh into a parametric solid model, which captures your design intent and can be modified and edited using standard CAD tools.

Combining high precision CMMs with the flexibility of 3D scanning.

A key benefit AB Technology offers with our Scan to CAD services is our ability to combine high resolution 3D scan data with high accuracy CMM data to give the ultimate digital representation of your part. While 3D scanners are great for capturing the overall shape and geometry of a part, there may be certain high-precision features that require additional verification. With our advanced CMMs, we can overcheck these features with an accuracy of just 0.003 mm, ensuring that the resulting CAD model is as accurate as possible. This added layer of precision makes our Scan to CAD services ideal for applications that require tight tolerances or have strict quality control requirements.

Scan to CAD offers a range of benefits, including:

Design intent capture: Our Scan to CAD service captures your design intent, making it easier to refine your product and respond to changes in your project requirements.

Defect removal: Any existing defects in the scanned part can be removed in the CAD model, ensuring that your final CAD model is of the highest quality.

High accuracy: Our scanning technology captures even the smallest details, ensuring that your CAD model is an accurate representation of the physical object.

Improved visualisation: With a 3D CAD model, you can view and manipulate your design from any angle, helping you to identify potential issues and make improvements before production.

Check out our reviews

We take pride in delivering exceptional customer service. Don’t just take our word for it – check out our Google reviews to see what our customers have to say about our expertise, attention to detail, and timely delivery.

Frequently Asked Questions

Can you scan my part to CAD?

Yes, we can scan your part and convert it into a parametric solid model using our Scan to CAD service. Our advanced 3D scanning and CMM equipment captures every detail of your part’s shape, allowing us to create a detailed mesh that serves as the basis for the CAD model.

Check out our Case Studies page for examples of our work.

Can you scan shiny / matt / transparent surfaces?

Yes. For parts that would otherwise be difficult to scan, we use a specialist self evaporating spray that leaves zero residue. It enables us to scan almost any material and surface finish, whilst also requiring no cleaning!

What CAD file formats can you supply?

We cover all common CAD file formats, both generic and native. Common 3D CAD file formats include .step, .igs, .stl and .obj. We can also supply 2D CAD of your part and drawings in formats such as .dxf and .pdf. See our downloads page for example data.

Can you output native CAD files?

We can supply native CAD file for Solidworks, Autodesk Inventor, AutoCAD, and Fusion 360.

How long does it take to scan to CAD?

The scanning process itself typically takes between a couple of hours and a day. The exact time it takes to create the CAD model depends on the complexity of the part and the number of features that need to be modelled. Most parts can be completed in just a few days, though a complex part or assembly may take several weeks. We work closely with our clients to provide accurate estimates and updates, with final high-quality CAD models delivered in a timely manner.

How much does it cost to scan a part to CAD?

The cost of our 3D scanning to CAD service varies depending on a number of factors, including the size and complexity of the object, and the desired level of accuracy.

To receive a personalised quote for your project, please send us a brief description and a few photos of the object you’d like to scan using our contact form or email us at enquiries@ab-technology.co.uk

Our prices include all costs associated with the project, including scanning, processing, and file delivery. There are no hidden fees.

If you’re interested in our 3D Scan to CAD service, please don’t hesitate to contact us today.

We’re ready to help you turn your real-world objects into high-quality digital models.

or read more about our other 3D scanning and reverse engineering services.

About Us

AB Technology started out as an independent CMM Inspection & Programming company based near Nottingham, UK. Over the last 25+ years, we have expanded our services to include 3D scanning and reverse engineering, serving customers of all sizes, across an array of industry sectors, both domestically and internationally.

Key Links

Contact Us

AB Technology (Newark) Ltd.

Unit 8, Crewe Close

Blidworth

Nottinghamshire

NG21 0TA

United Kingdom