Reverse Engineering Services

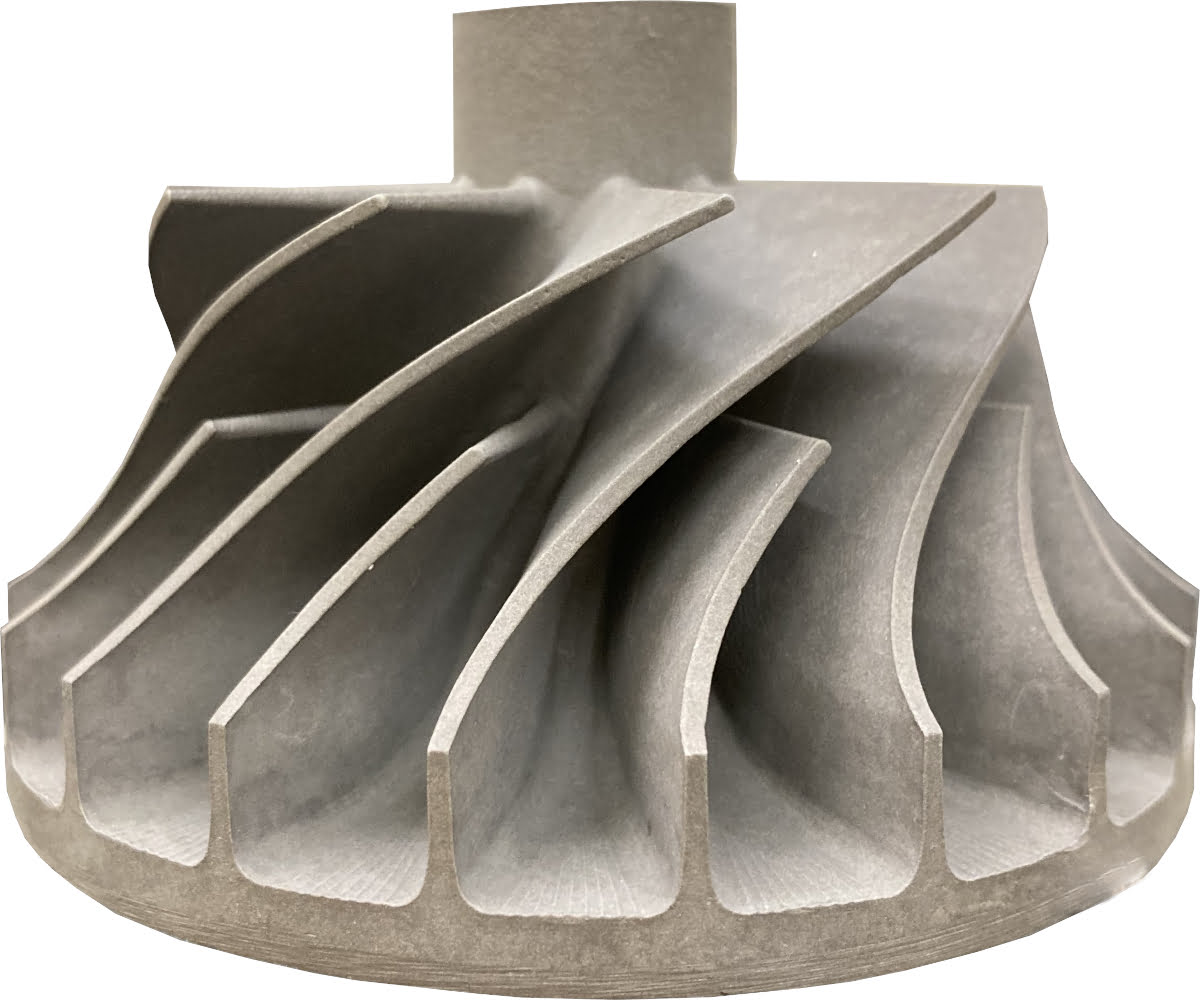

Transform physical parts into accurate 3D CAD models and production-ready drawings with our professional reverse engineering service.

From 3D scanning to design intent CAD modelling, our 30 years of metrology experience delivers the precision and detail you need.

Professional Reverse Engineering Solutions

With over 30 years of experience in dimensional metrology, AB Technology delivers precise reverse engineering services that capture legacy parts, document current manufacturing, and enable product development across aerospace, automotive, and manufacturing sectors.

Our comprehensive service combines multiple measurement technologies to create accurate 3D CAD models from physical components. We digitalise your parts using 3D scanning and CMM inspection, then transform the data into production-ready CAD models and detailed engineering drawings.

What You Receive:

- Design intent CAD models – Fully parametric solid/surface models in your preferred format (SolidWorks, STEP, IGES, Inventor, etc.)

- Engineering drawings – 2D drawings in PDF or DXF format dimensioned with GD&T as required

Quality Assurance: All work delivered under ISO 9001:2015 certification (Certificate No. 3001, ISOQAR).

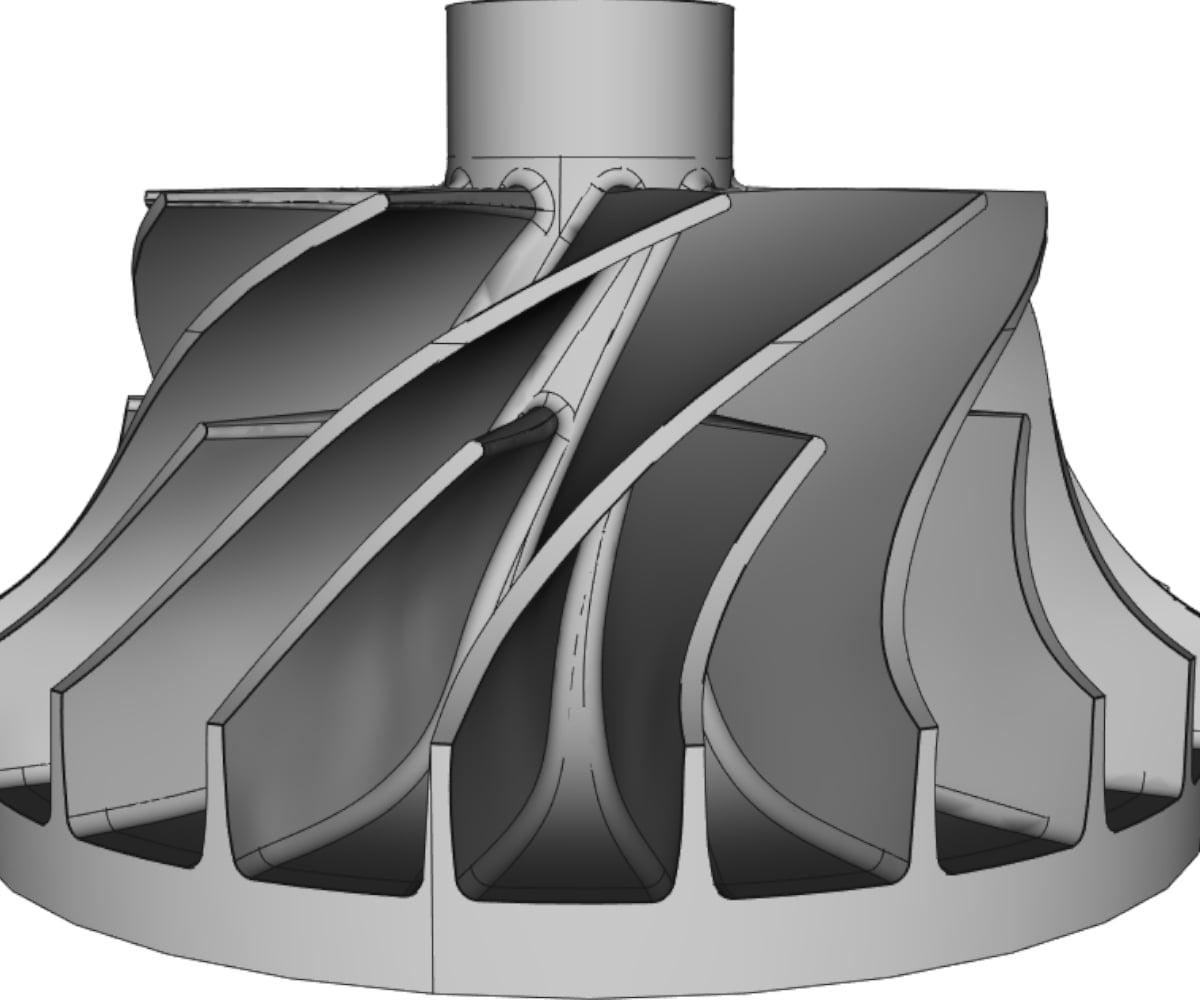

Component scan to CAD model comparison

Trusted by Manufacturing Professionals

Don’t just take our word for it. Our customers consistently rate us 5 stars for precision, turnaround times, and technical expertise.

Customer feedback:

“Outstanding work. Very quick turn around, accurate and faultless.”

Roger Osborne

Our Reverse Engineering Process

Step 1: Data Capture & 3D Scanning

Selecting the optimal measurement method is critical to project success. Our engineers assess your component’s geometry and required accuracy to recommend the most suitable approach.

Available Technologies:

Non-Contact 3D Scanning

Equipment: Shining 3D EinScan HX (hybrid laser), TranScan C (structured light)

Best for: Complex organic shapes, freeform surfaces, large assemblies

Accuracy: Up to 0.04mm

CMM Contact Measurement

Equipment: Renishaw REVO-2 5-axis systems with Renishaw Modus software

Best for: Prismatic features, critical dimensions, tight tolerances

Accuracy: Up to 0.003 mm

Hybrid Approach: We frequently combine multiple methods to capture both complex surfaces and critical dimensions in a single project, delivering optimal accuracy across all features.

Step 2: STL Mesh Generation

When 3D scanning is employed, we process the scanned point cloud data into a triangulated mesh (STL format). This creates an exact digital replica of your physical component, including any manufacturing variations, defects, or damage present in the sample.

The STL mesh serves as a CAD modelling baseline. A visual guide for surface creation and feature placement

Our engineers clean and optimise the mesh, removing noise while preserving genuine geometric features. Any defects or damage in the physical part can be identified at this stage and corrected in the subsequent CAD model as required.

Step 3: CAD Modelling & Engineering Drawings

Our CAD engineer creates a fully parametric, design intent 3D model from the measurement data. This is where expertise matters – we reconstruct not just the geometry, but the design logic behind it.

CAD Model Features:

- Parametric construction – Fully editable feature trees allowing future modifications

- Design intent capture – Geometric relationships and symmetry preserved

- Feature recognition – Standard features (holes, slots, radii) properly defined

- Clean geometry – Manufacturing defects removed, ideal form restored

- Multi-body/assembly capability – Complex parts modelled with proper structure

File Format Support:

Native formats: SolidWorks, Fusion 360, Parasolid

Universal formats: STEP (.stp/.step), IGES (.igs/.iges)

Check compatibility: Download example CAD files to test with your software

Engineering Drawings:

We produce detailed 2D drawings including:

- Drawing Dimensions inc. tolerancing

- Geometric Dimensioning & Tolerancing (GD&T)

- Custom views, sections, and detail callouts as needed

- Surface finish callouts (Ra values)

- Material specifications and heat treatment requirements

Please note: Customers will need to specify non-dimensional details for the drawing.

Quality Check: All CAD models are verified against the original scan data using colour deviation analysis. Overchecks are made using CMM & hand tools.

Industries We Serve

✈️

Aerospace

Legacy part support, tooling replication, and AS9100-ready documentation

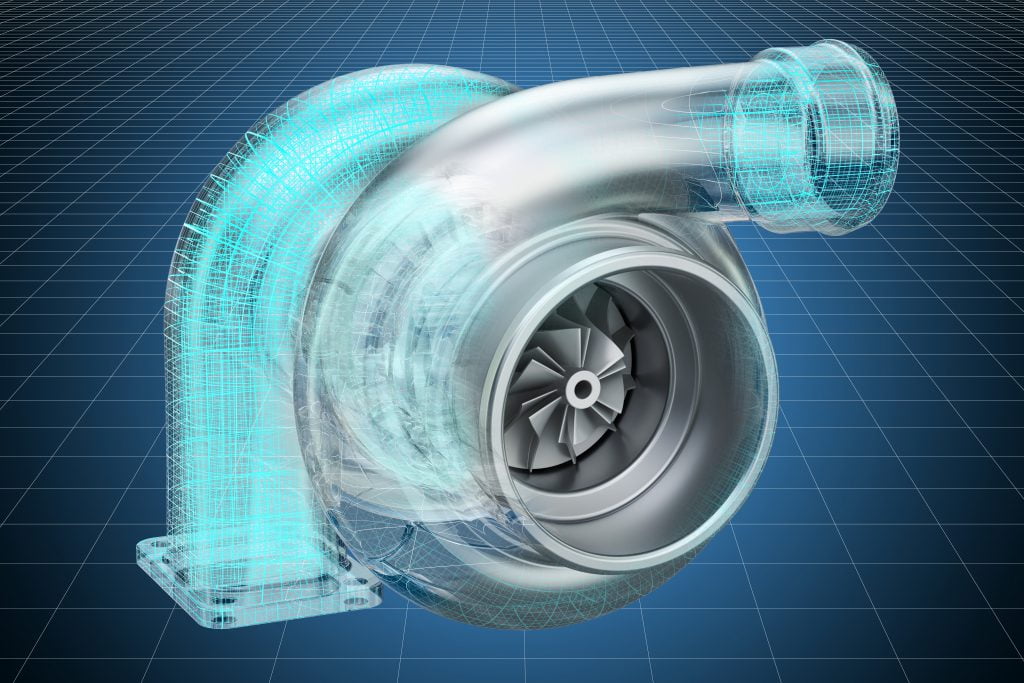

🚗

Automotive

Performance parts, custom manifolds, and prototype development

⚙️

Manufacturing

Production tooling, spare parts, and obsolescence management

Ready to Start Your Reverse Engineering Project?

Contact us today for a no-obligation quote. We’ll assess your requirements and recommend the best approach for your component.

ISO 9001:2015 Certified • 30 Years Experience • UK-Based Engineering Team