Case Studies

These case studies show how we use 3D scanning, reverse engineering and CMM inspection to solve real engineering problems.

Each example explains:

- what needed measuring or modelling

- how the data was captured and processed

- what was delivered and why it mattered

All projects were carried out using our own equipment, either on-site or in our temperature-controlled CMM lab. The work follows our ISO 9001 quality system and reflects our long-standing role as a Rolls-Royce approved supplier.

For more examples, see our 3D scanning portfolio. If you’d like to discuss a project, get in touch.

A Unique Reverse Engineering Project Combining CMM and 3D Laser Scanning

This case study demonstrates a hybrid reverse engineering workflow, combining 3D scanning to capture large areas of surface geometry with CMM inspection for internal features that could not be captured by 3D scanning. The approach resulted in an accurate solid CAD model with 100% coverage.

Author:

Metrology-as-a-Service provides Fast CMM Inspection

Case Study: Metrology-as-a-Service provides Fast CMM Inspection The problem A growing start-up developed a novel air compressor and had a prototype made by a third party. While setting up their factory they had no dedicated quality department to inspect parts. They needed fast, reliable visibility of part quality from their original supplier and from the […]

Author:

Minimising Production Downtime Using 3D Scanning

This case study details how we helped a customer upgrade their production line using 3D scanning technology. By capturing precise models of the machinery and its surroundings, we enabled a right-first-time design solution with minimal downtime.

Author:

Modern Techniques in Historic Preservation – 3D Scanning Vulcan Bomber XL426

As part of Vulcan XL426’s 2023/2024 winter restoration, we helped the Vulcan Restoration Trust by providing on-site 3D scanning and creating a digital model of their internal fuel tank.

Author:

Precision Window & Stonework Restoration with 3D Scanning Technology

Read about how we helped with the restoration of St Alban’s church, Retford, following a devastating fire. Through innovative use of 3D scanning, we helped the builders restoring the church to get a clean and elegant finish around the traditional windows.

Author:

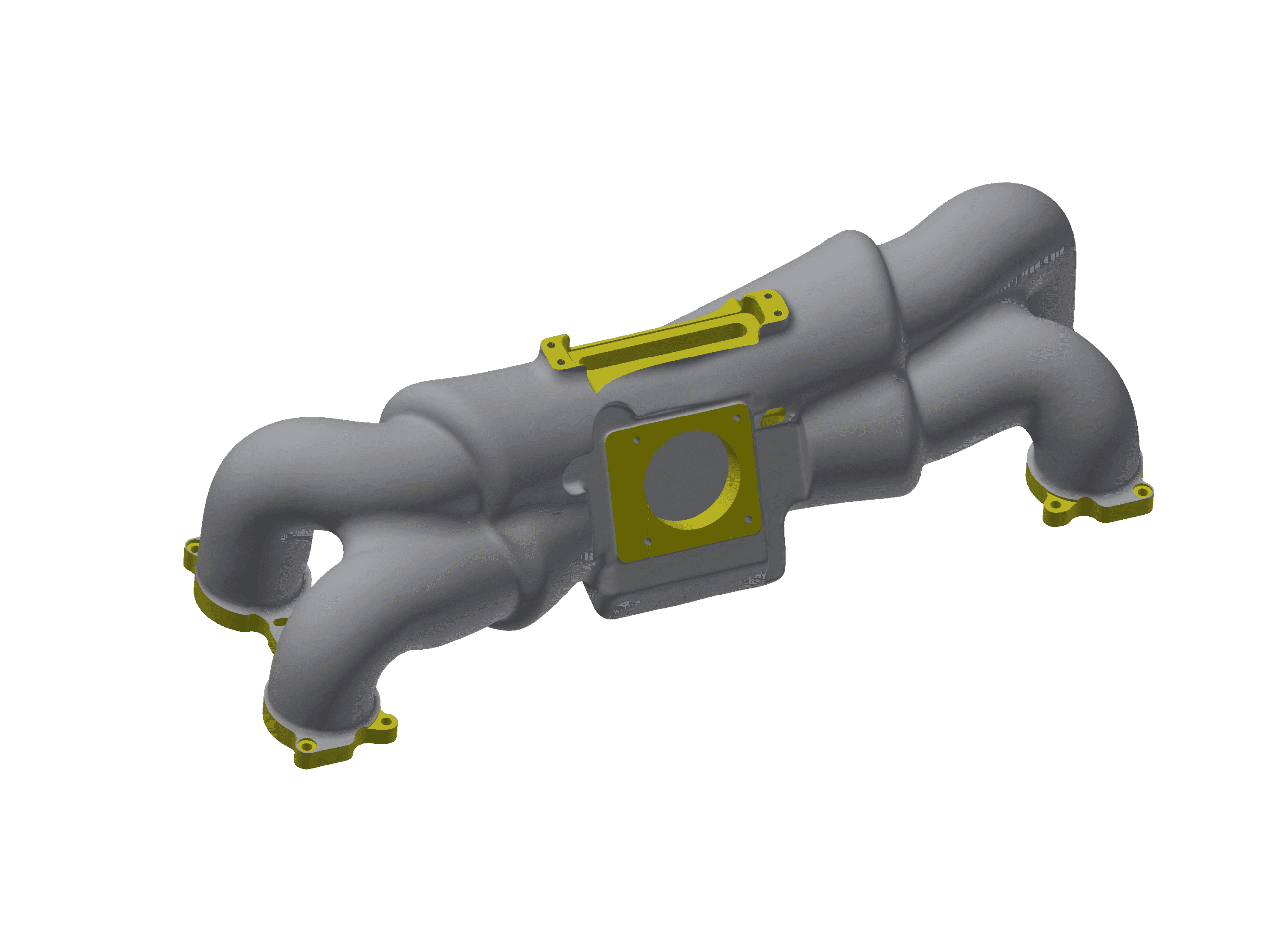

How We Reverse Engineered a Casting into a Custom Manifold

Our customer, a prominent player in the automotive aftermarket industry, approached us with a specific challenge: they needed a solution for creating a custom machined Subaru Impreza High Volume Inlet Manifold from a Cosworth Intake Manifold Casting.

Author:

Enabling CAD-based Product Design through Reverse Engineering a Bicycle Hanger

Our customer, a manufacturer of specialist bicycles, approached us with a challenge. They needed to fully model their bikes in CAD, but they lacked CAD models for the bought-out components. Specifically, they needed a CAD model for a bicycle hanger.

Author:

Combining 3D Scanning and Printing To Save A Door

Our customer required what should have been a simple replacement part for their door. However the design had changed since they installed the original door latch, meaning the current version is incompatible with older versions. Read how we helped avert the need to replace the whole door using 3D Scanning.

Author:

Preserving the Past | 3D Scanning a James Chesterman’s Metallic Tape Measure

Case Study: Preserving the Past by 3D Scanning of James Chesterman’s Metallic Tape Measure One of our experienced 3D scanning engineers, Robert, undertook a personal project to digitally preserve his great-grandfather’s James Chesterman’s Metallic Tape Measure. With over 10 years of metrology experience, Robert used a structured light scanner (150mm volume) with texture scan to […]

Author: